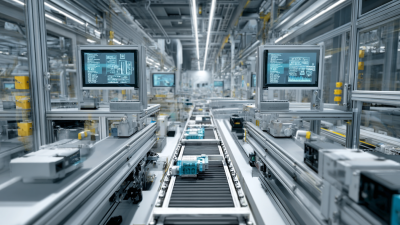

2025 Top Trends in Automation and Control Systems You Need to Know

As the landscape of automation and control systems continues to evolve, the year 2025 promises to unveil transformative trends that will redefine the industry. According to a recent report by MarketsandMarkets, the global automation and control systems market is expected to reach $300 billion by 2025, growing at a CAGR of 8.2%. This rapid growth is fueled by the increasing demand for operational efficiency and safety across numerous sectors, including manufacturing, oil and gas, and energy.

Industry expert Dr. Emily Roberts, the Chief Technology Officer at TechVision Solutions, emphasizes the critical role of innovation in this field, stating, "The integration of advanced technologies like AI and IoT into automation and control systems will not only enhance productivity but also pave the way for unprecedented levels of data-driven decision-making." As organizations seek to adapt to the digital landscape, understanding these emerging trends is essential for leveraging new opportunities and maintaining a competitive edge.

In this article, we will explore the top trends shaping the future of automation and control systems, from the rise of smart factories to the implementation of predictive maintenance techniques. By examining these developments, businesses can better prepare themselves for the advancements that lie ahead, ensuring they remain at the forefront of this rapidly changing industry.

Read more »

By:Isabella - December 6, 2025

By:Isabella - December 6, 2025

By:Isabella - December 4, 2025

By:Isabella - December 4, 2025

By:Oliver - December 2, 2025

By:Oliver - December 2, 2025

By:Oliver - December 1, 2025

By:Oliver - December 1, 2025

By:Isabella - November 29, 2025

By:Isabella - November 29, 2025

By:Isabella - November 27, 2025

By:Isabella - November 27, 2025

By:Isabella - November 26, 2025

By:Isabella - November 26, 2025

By:Oliver - November 24, 2025

By:Oliver - November 24, 2025

By:Oliver - November 23, 2025

By:Oliver - November 23, 2025

By:Oliver - November 22, 2025

By:Oliver - November 22, 2025

By:Sophia - November 20, 2025

By:Sophia - November 20, 2025

By:Sophia - November 19, 2025

By:Sophia - November 19, 2025

By:Sophia - November 14, 2025

By:Sophia - November 14, 2025

By:Isabella - November 12, 2025

By:Isabella - November 12, 2025

By:Sophia - November 11, 2025

By:Sophia - November 11, 2025