As we delve into the transformative landscape of industries in 2023, the significance of automation and controls cannot be overstated. In an era defined by rapid technological advancement and ever-evolving market demands, businesses are increasingly adopting innovative automation solutions to enhance efficiency, reduce costs, and improve overall productivity. The integration of advanced controls within this automation framework not only streamlines operations but also empowers organizations to swiftly adapt to changing conditions and consumer expectations.

The top trends shaping the future of automation and controls present exciting opportunities for various sectors, from manufacturing to healthcare. These trends encompass the adoption of artificial intelligence, the Internet of Things (IoT), and predictive analytics, all of which are driving a new wave of operational excellence. As industries seek to harness these advancements, it is crucial to understand how these trends are interlinked and how they can collectively revolutionize business processes. By examining the leading automation and controls trends of 2023, we can gain valuable insights into the direction of industrial evolution and the critical role these technologies play in fostering sustainable growth and competitiveness.

The integration of AI-powered automation in manufacturing processes is reshaping industrial landscapes in unprecedented ways. As industries strive for increased efficiency and precision, artificial intelligence emerges as a key driver of transformation. By harnessing vast amounts of data, AI systems can optimize production workflows, reduce downtime, and enhance product quality. This not only leads to significant cost savings but also enables manufacturers to respond swiftly to market demands and fluctuations.

Moreover, AI-powered automation promotes adaptability in manufacturing environments. Advanced algorithms can analyze operational performance in real-time, allowing for dynamic adjustments to processes as needed. This responsiveness ensures that manufacturers can maintain their competitive edge in an ever-evolving market. Additionally, the introduction of smart robotics—coupled with AI—facilitates collaborations between machines and human workers, leading to safer workplaces and improved overall productivity. As organizations embrace these technologies, the potential for innovation in manufacturing processes continues to expand, setting the stage for future advancements in automation across various sectors.

The integration of the Internet of Things (IoT) into automation and control systems has become a cornerstone in transforming industries in 2023. By harnessing real-time data monitoring, businesses can enhance their operational efficiency, reduce downtime, and make informed decisions swiftly. IoT devices collect vast amounts of data from various sensors across production lines, logistics, and supply chains, enabling companies to monitor their processes continuously. This instantaneous access to data helps organizations identify anomalies and trends, allowing for timely interventions that can prevent costly disruptions.

Moreover, the synergy between IoT and automation technologies empowers organizations to create more responsive and adaptable systems. With the ability to analyze real-time data, companies can optimize resource allocation and streamline workflows. Predictive maintenance is a significant advantage of this integration; by analyzing data patterns, companies can anticipate equipment failures before they occur, significantly reducing maintenance costs and enhancing the overall reliability of their operations. As industries continue to embrace this transformation, the integration of IoT will play a vital role in driving innovation and promoting sustainability within various sectors.

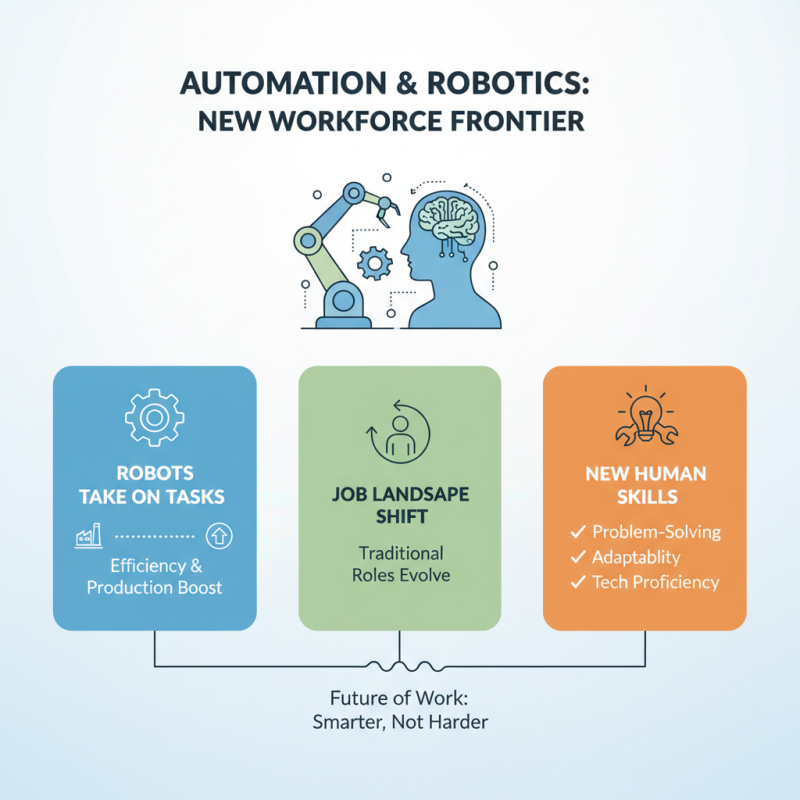

The rise of automation and robotics is reshaping workforce dynamics across various industries. As robots take on more complex tasks, the traditional job landscape is undergoing significant changes. This transformation not only streamlines operations and enhances productivity but also necessitates a shift in the skill sets required from human workers. Industries are increasingly seeking employees who possess advanced problem-solving abilities, adaptability, and technical proficiency to thrive in this new environment.

Tips for navigating this shift include investing in ongoing education and training programs that focus on digital skills and robotics. Organizations should encourage their employees to embrace lifelong learning and stay updated with emerging technologies. Additionally, fostering a collaborative atmosphere where humans and robots work together harmoniously can enhance efficiency and innovation.

As companies integrate advanced robots into their workflows, it is crucial to address potential job displacement concerns. By emphasizing the importance of reskilling and upskilling, businesses can better prepare their workforce for roles that complement robotics rather than compete against them. Engaging in open dialogues about the benefits of automation can also help alleviate fears and promote a positive outlook on the future of work.

As automation becomes increasingly integral to various industries, the cybersecurity challenges associated with automated control systems have emerged as a critical concern. These systems, which manage everything from manufacturing processes to critical infrastructure, are potent targets for cyber attackers. The interconnected nature of modern automation systems means that a breach in one area can ripple through an entire organization, potentially leading to significant operational disruptions and data breaches.

The complexity of control systems contributes to their vulnerability. Many organizations struggle to maintain up-to-date security protocols amidst rapid technological advancements. Legacy systems, often still in use, may not support modern cybersecurity measures, leaving gaps that can be exploited.

Additionally, as the workforce evolves, the introduction of remote access and cloud technologies further complicates the security landscape, creating more entry points for potential threats. To mitigate these risks, industries must prioritize comprehensive cybersecurity strategies that not only protect existing systems but also anticipate future vulnerabilities that may arise as automation continues to evolve.

The ongoing shift towards sustainability in various industries is increasingly being facilitated by automation technologies. In 2023, businesses are integrating automated systems designed specifically to minimize waste and reduce energy consumption. This trend not only boosts operational efficiency but also aligns with global sustainability goals, making it a win-win scenario for both companies and the environment.

Automation offers the potential to optimize resource usage by analyzing data in real-time and adjusting processes accordingly. For instance, smart sensors can monitor energy use and detect inefficiencies, allowing companies to make immediate adjustments to save resources. Additionally, automation in supply chain management can reduce excess inventory, leading to less waste and a more streamlined operation.

Tips for achieving sustainability through automation include conducting a thorough audit of current processes to identify areas for improvement, investing in smart technologies that provide actionable insights, and fostering a culture of continuous improvement among employees. Regular training on sustainability practices can empower teams to recognize their impact and contribute actively to waste reduction initiatives. Embracing these automation strategies can significantly enhance an organization's commitment to environmental stewardship while also yielding cost savings.

This chart illustrates the key trends in automation and controls focusing on sustainability, waste reduction, and energy consumption across various industries in 2023.