Control systems automation is a vital aspect of modern industry. It enhances efficiency and accuracy across various applications. Understanding its principles can be complex yet rewarding. Many industries rely on these systems for routine tasks.

Automation minimizes human intervention. However, it can lead to over-reliance on technology. This raises questions about control and safety. Some processes may become too dependent on automated systems, risking potential failures.

Effective control systems automation requires a thoughtful approach. Despite advancements, challenges remain that require constant reflection. Understanding the balance between automation and human oversight is crucial for success. Exploring these themes will provide insights into the ever-evolving landscape of control systems automation.

Control systems automation is a fascinating field. It combines engineering principles with technology. The essence lies in understanding how systems behave and interact. This understanding helps in designing effective automation solutions. Monitoring, control, and feedback are key components. They ensure processes operate smoothly and efficiently.

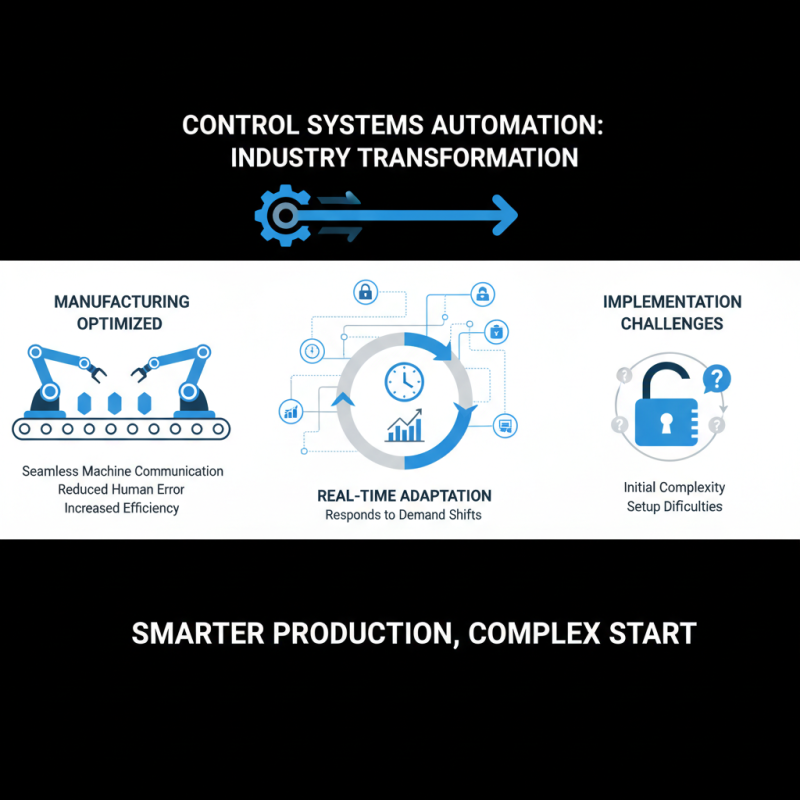

Real-world applications are widely diverse. Industrial manufacturing lines rely on these systems for precision. For example, robotic arms automate assembly tasks. This reduces human error and increases efficiency. However, not every implementation is flawless. Some systems may lack adaptability. This can lead to unexpected downtime. Reflecting on these challenges is crucial for improvement.

Moreover, the principles of control systems automation must be well-grounded. Feedback loops are foundational concepts. They allow the system to self-correct. But, inaccuracies can arise from poor sensor data. This aspect requires constant evaluation. Striving for higher accuracy is essential. Recognizing that imperfections exist fuels the drive for better solutions.

Control systems play a crucial role in automation. They help manage various processes in industries, enhancing efficiency and precision. Understanding their components is essential for effective application. At the core of these systems are sensors. They gather real-time data, allowing systems to respond quickly to changes. This data accuracy is vital for decision-making.

Next, actuators bring the control systems to life. They execute commands from the control unit, converting signals into actions. Common examples include motors and valves. Their reliability can make or break a system. Yet, challenges arise. If sensors fail, the entire control loop can become erratic. It’s crucial to constantly monitor these components.

The control unit itself is the brain of the operation. It processes data and sends commands to the actuators. Programmable logic controllers (PLCs) are frequently used here. However, programming these units can be complex. Mistakes in code might lead to unexpected results. Careful attention is necessary to avoid disruptions. This balance of precision and reliability defines successful automation in control systems.

Control strategies are crucial in automation. Two primary types exist:

open-loop and closed-loop systems.

Open-loop control systems perform actions without feedback. They rely on predetermined inputs and provide less accuracy. An example is a simple irrigation system. It operates based on a timer, not considering the soil moisture level.

Closed-loop control systems utilize feedback. They measure the output and adjust inputs accordingly. This method enhances precision and adaptability. For instance, modern HVAC systems use sensors to maintain desired temperatures. According to a recent industry report, closed-loop systems can increase efficiency by 30%. However, they also complicate design and maintenance.

Although closed-loop systems are efficient, challenges exist. Feedback delays can cause instability. Furthermore, if sensors fail, the system may not function optimally. Some industries still prefer open-loop systems for their simplicity. Striking a balance between complexity and performance is key in choosing the right control strategy.

Control systems automation is transforming several industries. In manufacturing, it optimizes production lines. Machines communicate seamlessly. This reduces human error and boosts efficiency. Automated systems adjust operations in real time. They respond to shifts in demand. However, the initial setup can be complex. Not all companies manage to implement these systems successfully.

In agriculture, control systems monitor soil conditions. They automate irrigation processes based on weather data. This leads to better resource management. Yet, reliance on technology can be risky. Equipment failures may disrupt crops. Regular maintenance is crucial. The balance between automation and manual oversight must be evaluated.

Energy sectors also benefit from these systems. Smart grids optimize energy distribution. They adapt to consumption patterns. This increases sustainability. But, integration challenges exist. Older infrastructure may hinder progress. It’s essential to revisit existing frameworks to maximize potential. Embracing automation requires careful consideration of both benefits and drawbacks.

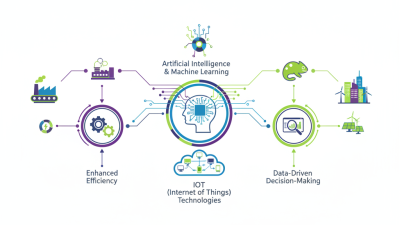

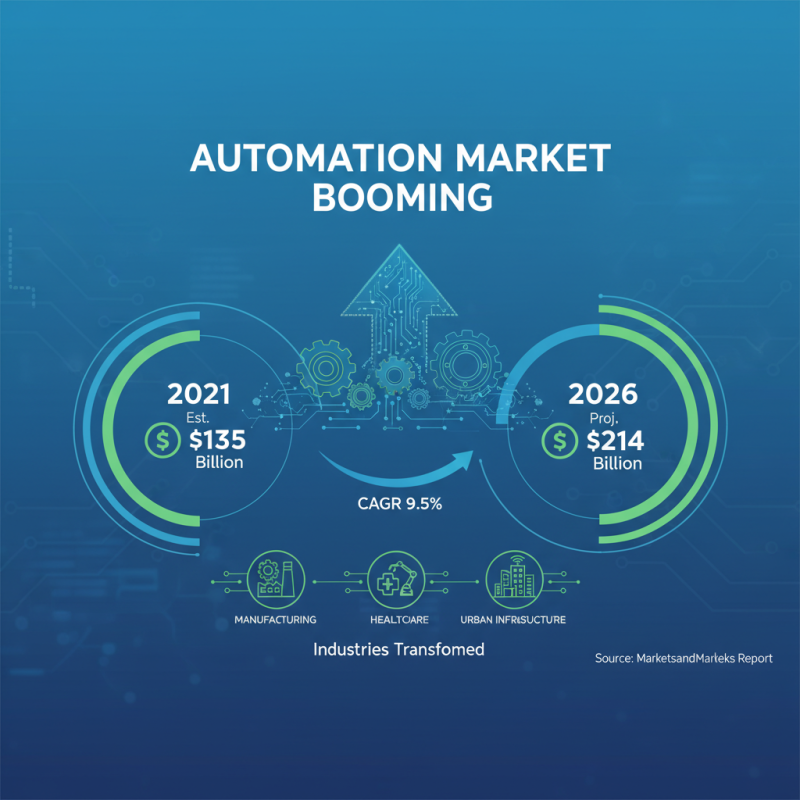

The world of control systems automation is rapidly evolving. Innovations are shaping industries, from manufacturing to healthcare. According to a recent report from MarketsandMarkets, the global automation market is projected to reach $214 billion by 2026. This represents a CAGR of 9.5% from 2021. Such growth demonstrates the increasing reliance on automated solutions.

Emerging trends include the integration of artificial intelligence (AI) and machine learning. These technologies enhance predictive maintenance and improve process accuracy. However, the adoption of these innovations raises concerns about cybersecurity risks. A survey by McKinsey highlights that 61% of companies face threats related to automation systems. Addressing these vulnerabilities is crucial for future success.

Another important aspect is workforce implications. Automation can lead to job displacement but also creates new roles. According to the World Economic Forum, 97 million new jobs may emerge by 2025 due to automation. However, adapting the workforce requires significant effort. Skill gaps may hinder the transition to this automated age. Organizations must rethink training programs to prepare for these changes effectively.