As we look ahead to 2025, the realm of control systems automation is poised for significant advancements that promise to reshape industries across the globe. Industry expert Dr. Emily Carter, a leading authority in automation technologies, emphasizes the critical shift occurring within this sector, stating, "The future of control systems automation hinges on our ability to integrate innovative technologies that enhance efficiency and adaptability." This evolution is not merely a trend but a necessary progression to meet the increasing demands of modern manufacturing and operational efficiency.

In the coming years, we can expect to see a host of transformative trends within control systems automation that will redefine how businesses approach their processes. From the rise of artificial intelligence and machine learning to the implementation of IoT (Internet of Things) technologies, these developments are set to enhance data-driven decision-making and streamline operations. As organizations strive for competitive advantages, understanding these trends will be vital in harnessing the full potential of control systems automation.

Ultimately, by staying ahead of the curve and embracing these changes, industries can leverage control systems automation to not only boost their operational performance but also foster innovation and sustainability in their practices. The landscape of automation is evolving, and those who adapt will lead in the new era of technological advancement.

The integration of artificial intelligence (AI) and machine learning (ML) into control systems is revolutionizing the way industries manage and optimize their operations. By harnessing the vast amounts of data generated by modern sensors and IoT devices, these technologies enable control systems to make informed decisions in real time. This shift enhances predictive maintenance, allowing systems to identify potential failures before they occur, thereby increasing operational efficiency and reducing downtime.

Moreover, AI and ML algorithms empower control systems to learn from historical data, leading to continuous improvement in performance. As they adapt to changing conditions, these systems can optimize processes, minimize energy consumption, and improve product quality. The emergence of smart control strategies is enabling industries to transition towards more autonomous operations, where human intervention is minimized, and systems can self-correct or adjust based on environmental feedback.

This not only streamlines workflows but also opens new avenues for innovation across various sectors.

As we look ahead to 2025, the focus on cybersecurity within industrial automation is becoming increasingly critical. With the growing interconnectedness of devices and systems, the vulnerability to cyber threats is rising significantly.

Industrial control systems, once seen as isolated environments, are now part of a broader digital ecosystem that is more susceptible to hacking and other malicious activities. This shift necessitates a proactive approach to cybersecurity, emphasizing the need for robust defense mechanisms and continuous monitoring to protect sensitive data and maintain operational integrity.

Furthermore, organizations are recognizing that integrating cybersecurity into their automation strategies is not just a necessity but a competitive advantage. Companies are investing in advanced cybersecurity solutions, adopting frameworks that prioritize risk assessment, incident response, and recovery plans tailored to their specific operational environments.

Training staff on cybersecurity protocols and cultivating a security-conscious culture within the workforce is equally essential.

As industrial automation continues to evolve, forward-thinking businesses are taking deliberate steps to safeguard their infrastructure, ensuring resilience against emerging cyber threats while maximizing efficiency and productivity.

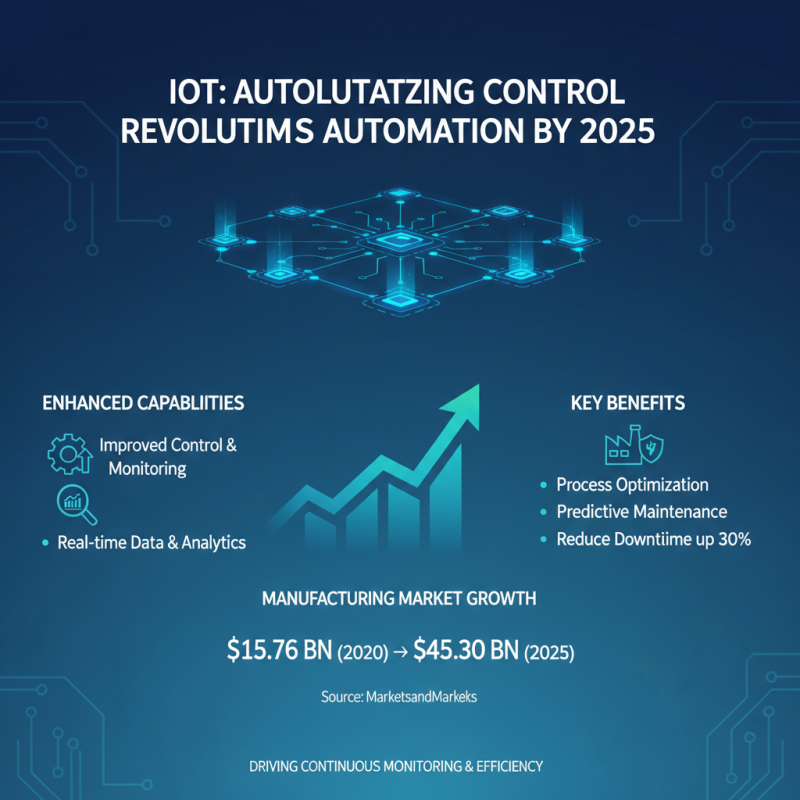

The Internet of Things (IoT) is set to revolutionize control systems automation by 2025, enhancing both control and monitoring capabilities across industries. According to a recent report from MarketsandMarkets, the IoT in manufacturing market is expected to grow from $15.76 billion in 2020 to $45.30 billion by 2025, driven by the need for continuous monitoring and optimization of production processes. This integration allows for real-time data collection and analysis, improving overall system efficiency and enabling predictive maintenance, which can reduce downtime by up to 30%.

Furthermore, as organizations increasingly seek to improve operational resilience, the convergence of IoT technologies with existing control systems facilitates more streamlined processes. A report by Deloitte highlights that 70% of manufacturing executives believe IoT implementations will lead to better decision-making capabilities. The enhanced visibility provided by IoT sensors and devices allows for immediate adjustments to production lines, minimizing resource wastage and increasing output. In sectors ranging from energy to pharmaceuticals, the capability to monitor systems remotely and respond proactively to performance issues will position businesses to thrive in a highly competitive landscape.

As we look towards 2025, the focus on sustainable automation practices and green technologies in control systems is becoming increasingly pronounced. Companies are recognizing the importance of integrating eco-friendly solutions into their automation processes. This shift is driven by the urgent need to reduce carbon footprints and enhance energy efficiency. Innovative technologies such as energy-efficient sensors and smart control algorithms are being developed to optimize operations while minimizing resource consumption. These advancements not only lead to cost savings but also contribute to a cleaner environment.

Moreover, the adoption of renewable energy sources is reshaping automation strategies. Organizations are now looking to seamlessly integrate solar, wind, and bioenergy into their existing systems, making use of advanced grid management technologies. The implementation of such green technologies not only ensures compliance with environmental regulations but also promotes a sustainable business model. Additionally, fostering a culture of sustainability within the workforce can lead to new ideas and improvements in automation processes, ultimately driving innovation and competitive advantage in the industry.

| Trend | Description | Impact on Sustainability | Expected Adoption Rate (%) |

|---|---|---|---|

| AI and Machine Learning | Integration of AI for predictive maintenance and operational efficiency. | Reduces energy consumption and minimizes waste. | 75% |

| Green Technologies | Adoption of renewable energy sources in automation systems. | Decreases carbon footprint significantly. | 70% |

| IoT Integration | Use of IoT devices for real-time monitoring and control. | Enhances energy efficiency and resource management. | 80% |

| Cybersecurity | Increased focus on securing automation systems from cyber threats. | Ensures sustainable operations without disruptions. | 65% |

| Sustainable Practices | Development of practices that promote sustainable production. | Encourages resource efficiency and waste reduction. | 60% |

The landscape of intelligent automation is evolving rapidly, particularly with advancements in robotics set to redefine control systems by 2025. According to a recent report by the International Federation of Robotics, the deployment of industrial robots is projected to exceed 4 million units globally by 2025, showcasing an annual growth rate of 10% from previous years. This surge is not just a reflection of increased adoption; it's indicative of a broader trend where businesses leverage robotics to enhance efficiency, precision, and flexibility in manufacturing and other sectors.

One of the key elements driving this advancement is the integration of AI with robotics. These intelligent automation solutions enable robots to learn and adapt in real-time, making them more responsive to changing environments and tasks. According to a 2023 study from the Institute for Robotic Process Automation and AI, enterprises that adopted AI-enhanced robotic systems reported efficiency improvements of up to 40%. This integration is pivotal for achieving operational excellence and meeting the evolving demands of the market.

Tips: When considering the implementation of intelligent automation in your operations, assess your current processes to identify areas where robotics can add the most value. Additionally, invest in training your workforce to work alongside these technologies, as human expertise remains crucial in guiding automated systems effectively. Staying informed on these trends can give your organization a competitive edge as we approach 2025 and beyond.