In the pursuit of operational excellence, businesses across various industries are increasingly turning to automated process control as a means to enhance efficiency and reduce costs. As we approach 2025, the implementation of automated process control systems has become a critical factor in optimizing production workflows and ensuring consistency in output. This technological advancement not only streamlines repetitive tasks but also provides real-time data analytics that empower organizations to make informed decisions swiftly, allowing them to remain competitive in a rapidly evolving market.

The integration of automated process control is not merely a trend; it is a transformation that can redefine how companies operate. By harnessing the capabilities of automation, businesses can minimize human error, reduce waste, and improve overall productivity. However, effective implementation requires careful planning and a thorough understanding of existing processes to identify areas where automation can yield the highest returns. As organizations navigate this journey, focusing on strategic alignment and employee training will be essential to maximize the benefits of automated process control and drive sustainable growth.

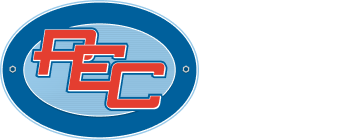

Automated Process Control (APC) stands at the forefront of modern industrial efficiency, harnessing advanced technologies to optimize production processes. Concepts such as feedback loops, real-time data analysis, and machine learning algorithms play a crucial role in the deployment of APC systems. According to a report by the International Society of Automation, industries that adopt these technologies can achieve efficiency improvements of up to 30%, while simultaneously reducing operational costs by approximately 20%. This emphasizes the transformative potential of APC in various sectors, including manufacturing, pharmaceuticals, and energy.

The benefits derived from implementing automated process control are multifaceted. Enhanced precision in operations minimizes human error and variance in production quality, leading to consistently high standards. Additionally, the ability to gather and analyze data in real-time facilitates proactive decision-making, allowing operators to adjust processes dynamically as conditions change. A survey conducted by the Automation Federation revealed that companies leveraging APC report a 25% increase in production output, highlighting not just immediate financial gains but long-term sustainability advantages. By integrating automation into process control, organizations not only improve efficiency but also position themselves favorably in the competitive landscape, adapting swiftly to evolving market demands.

The evolution of automated process control systems has revolutionized industries by significantly enhancing operational efficiency. Key technologies such as advanced sensors, machine learning algorithms, and IoT connectivity are at the forefront of this transformation. According to a recent report by the International Society for Automation, the adoption of advanced sensor technologies can improve data accuracy by over 30%, enabling real-time monitoring and quicker responses to process variations. These sensors facilitate the collection of critical operational data, which, when processed using sophisticated algorithms, helps in identifying patterns and predicting potential issues before they escalate.

The evolution of automated process control systems has revolutionized industries by significantly enhancing operational efficiency. Key technologies such as advanced sensors, machine learning algorithms, and IoT connectivity are at the forefront of this transformation. According to a recent report by the International Society for Automation, the adoption of advanced sensor technologies can improve data accuracy by over 30%, enabling real-time monitoring and quicker responses to process variations. These sensors facilitate the collection of critical operational data, which, when processed using sophisticated algorithms, helps in identifying patterns and predicting potential issues before they escalate.

Additionally, the integration of IoT in automated process control systems has created a seamless communication channel between devices, allowing for better coordination and management of resources. A study published by McKinsey & Company found that companies implementing IoT in their operations experienced up to a 40% reduction in downtime due to predictive maintenance capabilities. Machine learning further enhances these systems by optimizing control strategies based on historical data, leading to improved process stability and reduced operational costs. In essence, the convergence of these technologies not only boosts efficiency but also paves the way for more sustainable and resilient manufacturing processes.

Additionally, the integration of IoT in automated process control systems has created a seamless communication channel between devices, allowing for better coordination and management of resources. A study published by McKinsey & Company found that companies implementing IoT in their operations experienced up to a 40% reduction in downtime due to predictive maintenance capabilities. Machine learning further enhances these systems by optimizing control strategies based on historical data, leading to improved process stability and reduced operational costs. In essence, the convergence of these technologies not only boosts efficiency but also paves the way for more sustainable and resilient manufacturing processes.

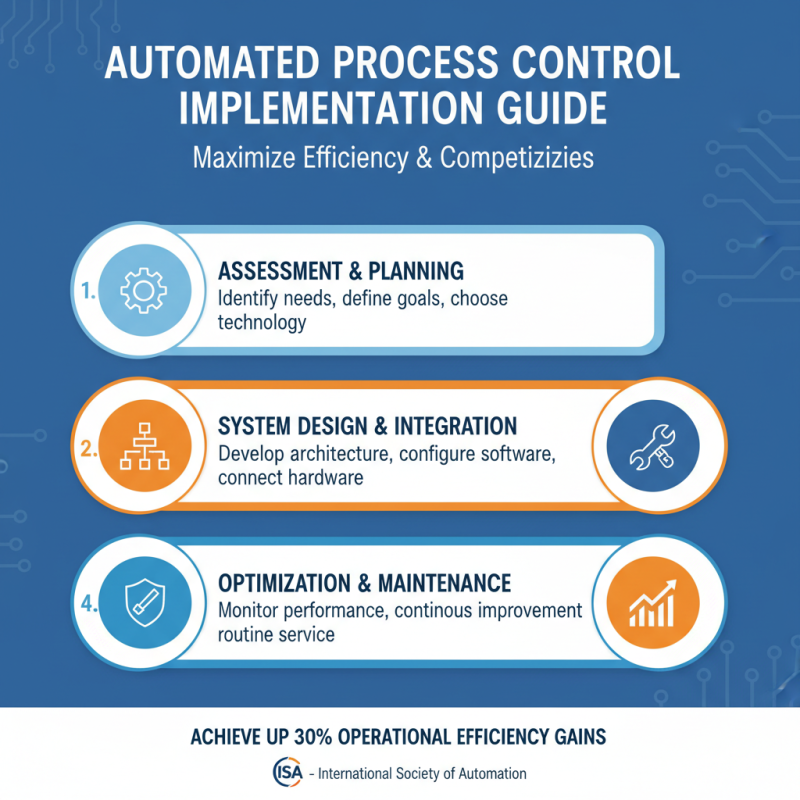

Implementing automated process control is crucial for maximizing efficiency in today’s competitive industrial landscape. According to a report by the International Society of Automation, organizations that adopt automated systems can achieve operational efficiencies of up to 30%. This step-by-step guide outlines essential phases for successful implementation.

First, it is vital to conduct a thorough analysis of current processes. Identify bottlenecks and inefficiencies through data collection and performance metrics. The Automation Industry Association suggests employing continuous process improvement methodologies, such as Lean or Six Sigma, to establish a baseline. Once critical areas are identified, it's time to set clear objectives for automation, such as reducing downtime or increasing throughput.

Next, develop a strategic plan that encompasses technology selection, integration, and employee training. A study by McKinsey & Company indicates that 70% of transformation programs fail due to lack of employee engagement. Including staff in the automation journey through workshops or training sessions can facilitate smoother transitions. Additionally, ensure that the technology platforms chosen are scalable and interoperable with existing systems to maximize return on investment and foster long-term growth in automation capabilities.

To effectively measure and analyze efficiency gains with automation in 2025, organizations must focus on key performance indicators (KPIs) that align with their operational goals. A recent industry report from McKinsey highlights that companies implementing automated process control can achieve up to a 30% increase in productivity within the first year. This productivity boost can be measured through metrics such as cycle time reduction, accuracy rates, and overall throughput. Utilizing real-time data analytics will empower businesses to constantly assess the impact of automation on their performance and make necessary adjustments.

When analyzing efficiency gains, it’s essential to adopt a comprehensive approach. Implementing visualization tools can aid in understanding complex data sets, allowing teams to easily track progress over time. Moreover, workforce training plays a crucial role; a study from PwC shows that companies that invest in employee upskilling in tandem with automation strategies report a higher return on investment.

Tips: Regularly review the collected data to identify trends or anomalies early on. Establish a feedback loop with your teams to ensure that the insights gained are actionable and lead to continuous improvement. Maintaining an agile approach will enable organizations to pivot as new automation technologies emerge and efficiencies evolve.

This chart illustrates the efficiency gains from automated process control across various industries in 2025. The data shows the percentage increase in efficiency, demonstrating how automation impacts different sectors.

As industries increasingly turn towards automation, the trend of incorporating advanced automated process control systems is gaining significant momentum. According to a recent report by McKinsey, companies that effectively implement automation can increase productivity by up to 30% within the first year. This rise is largely attributed to reduced manual intervention, enabling faster decision-making processes and a decrease in human error. Industries such as manufacturing, energy, and pharmaceuticals are harnessing these technologies to streamline operations, cut costs, and enhance overall efficiency.

Furthermore, the integration of machine learning and AI in automated process control is revolutionizing how organizations optimize their workflows. A study by Deloitte indicates that organizations utilizing AI-driven analytics can improve process efficiency by 20-40%. These tools allow for real-time monitoring and predictive maintenance, which minimize downtime and enhance operational reliability. As we move towards 2025, the emphasis will be on adopting these intelligent systems that not only increase efficiency but also promote sustainability and resilience in operations, positioning companies to thrive in a rapidly changing technological landscape.

| Dimension | Description | Current State | Target State (2025) | Improvement (%) |

|---|---|---|---|---|

| Data Integration | Seamless connection of data sources | 60% | 95% | 58% |

| Real-time Monitoring | Continuous oversight of processes | 70% | 100% | 43% |

| Predictive Analytics | Using data to forecast outcomes | 50% | 85% | 70% |

| Automation Level | Extent of process automation | 65% | 98% | 51% |

| Skill Development | Training for workforce | 40% | 90% | 125% |