In the rapidly evolving landscape of technology, the implementation of control systems automation has emerged as a pivotal strategy for organizations seeking to enhance operational efficiency. As we look towards 2025, the integration of automated control systems is not just an option; it is a necessity for businesses aiming to thrive in an increasingly competitive environment. This transformation allows for real-time data analysis, streamlined processes, and reduced human error, all contributing to a more agile and responsive operational framework.

One of the key advantages of control systems automation lies in its ability to optimize resource allocation and minimize downtime. By leveraging advanced technologies such as artificial intelligence and machine learning, organizations can gain deeper insights into their operational processes and make informed decisions that drive productivity. The focus should not only be on the technology itself but also on creating a comprehensive strategy that encompasses training, infrastructure, and continuous improvement practices to fully harness the potential of automation.

As we approach 2025, the stakes are higher than ever. Businesses that fail to implement effective control systems automation risk being left behind, unable to meet the demands of their customers or adapt to market changes. This article will explore various methodologies for adopting control systems automation successfully, ensuring organizations can achieve maximum efficiency and maintain a competitive edge in their respective industries.

Identifying key automation opportunities in control systems is crucial for enhancing efficiency and productivity in any organization. The first step is to conduct a thorough assessment of current operations. This involves analyzing workflow processes to pinpoint bottlenecks that slow down productivity. Utilizing data analytics tools can help gather insights into system performance, allowing teams to recognize areas ripe for automation. For example, tasks that require repetitive manual input are often ideal candidates for automation, as they can be streamlined to reduce error rates and increase speed.

Once potential areas for automation are identified, it’s essential to evaluate the integration capabilities of existing systems. This assessment should focus on how well new automation tools can mesh with current infrastructure, avoiding disruptions during the implementation phase. Engaging cross-functional teams during this evaluation can provide diverse perspectives on process improvements. Furthermore, pilot testing automation solutions on a smaller scale can yield valuable feedback and allow for adjustments before a wider rollout. This strategic approach ensures that the most impactful automation opportunities are prioritized, setting the stage for significant efficiency gains in control systems.

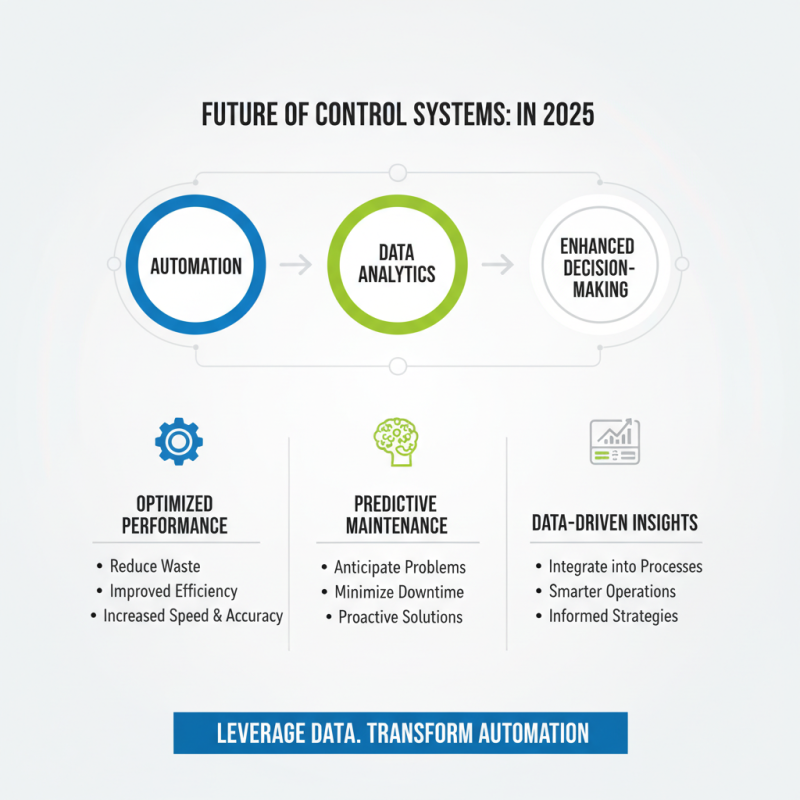

In 2025, as industries continue to embrace automation, leveraging data analytics will be crucial for enhanced decision-making within control systems. By integrating data-driven insights into automation processes, organizations can optimize performance, reduce waste, and improve overall operational efficiency. This shift not only increases speed and accuracy but also enables predictive maintenance, allowing businesses to anticipate problems before they occur, thus minimizing downtime.

**Tips for Effective Data Utilization in Automation:**

1. **Real-Time Data Monitoring:** Ensure that your control systems are equipped with real-time data monitoring tools. This allows for immediate feedback and quicker response times, enhancing the agility of your automated systems.

2. **Data-Driven Culture:** Foster a workplace culture that prioritizes data-driven decision-making. Encourage teams to analyze data trends and patterns regularly to inform operational strategies, enhancing overall productivity.

3. **Training and Skill Development:** Equip your team with the necessary skills in data analytics. Training employees on data interpretation and analytical tools will empower them to make informed decisions that support automation efforts.

Utilizing data analytics effectively can transform control systems, providing actionable insights that drive sustained improvements in efficiency and productivity throughout the automation journey.

The integration of AI and machine learning into control systems is poised to revolutionize automation, driving unprecedented efficiency across various industries. According to a recent report by McKinsey, organizations that leverage AI and machine learning can expect a productivity boost of up to 40%, significantly enhancing operational performance. By intelligently analyzing vast amounts of data generated by control systems, these technologies enable real-time decision-making, predictive maintenance, and optimization of processes, ultimately leading to reduced downtime and lower operational costs.

Furthermore, the implementation of AI enhances the adaptability of control systems to changing conditions. For instance, research from PwC indicates that 54% of executives believe AI can enhance productivity in their companies. In 2025, as these technologies become increasingly sophisticated, organizations that adopt AI-driven control systems can dynamically adjust to fluctuating demands and optimize resource allocation. This ability to learn from new data and improve over time not only fosters efficiency but also drives innovation, paving the way for smarter and more resilient manufacturing environments.

In order to successfully implement control systems automation, training employees effectively is paramount. Employees must be well-versed not only in the technology itself but also in how it integrates with existing processes. A structured training program that combines theoretical knowledge with hands-on experience can significantly enhance employees' confidence and competency. Workshops, simulation exercises, and interactive sessions can be beneficial, allowing employees to engage with the systems in a controlled environment before they are applied in real-world scenarios.

Moreover, fostering a culture of continuous learning is essential. Regularly scheduled training sessions that update employees on the latest advancements in automation technology will ensure they remain proficient. Encouraging teamwork in training settings promotes knowledge sharing, enabling employees to learn from one another's experiences. Feedback mechanisms should also be established to assess the effectiveness of the training, allowing for adjustments and improvements to be made based on employees’ insights and challenges encountered during the automation integration process. By prioritizing comprehensive training, organizations can empower their workforce to leverage automated control systems effectively, paving the way for maximum operational efficiency.

This bar chart represents the estimated training hours dedicated to employees on automated control systems across various industries in 2025.

Measuring the ROI of control systems automation initiatives in 2025 is crucial for organizations aiming to enhance operational efficiency and profitability. According to a recent report by Deloitte, businesses that implement automation in their control systems can expect an average return on investment of up to 30% within the first two years. This significant ROI is attributed to reduced operational costs, improved process accuracy, and increased productivity. As organizations continue to adopt automation technologies, understanding the financial metrics associated with these initiatives becomes essential for justifying expenditures and guiding future investments.

In 2025, measuring the effectiveness of control systems automation will likely rely heavily on key performance indicators (KPIs) such as productivity rates, error reduction, and time savings. A study from McKinsey highlighted that companies experience a 60% decrease in operational errors after implementing automated control systems, directly correlating to lower rework costs and enhanced customer satisfaction. Additionally, organizations that effectively utilize data analytics to track these metrics can pinpoint areas of improvement, leading to even greater efficiencies. As the landscape of control systems evolution continues, establishing a robust framework for measuring ROI will be indispensable for organizations seeking to remain competitive in an increasingly automated world.

| Automation Initiative | Initial Investment ($) | Annual Savings ($) | Payback Period (Years) | ROI (%) |

|---|---|---|---|---|

| Process Automation | 150,000 | 75,000 | 2 | 50% |

| Quality Control Automation | 200,000 | 60,000 | 3.33 | 30% |

| Inventory Management Automation | 100,000 | 40,000 | 2.5 | 40% |

| Energy Management Automation | 120,000 | 50,000 | 2.4 | 41.67% |

| Maintenance Scheduling Automation | 80,000 | 30,000 | 2.67 | 37.5% |