In the rapidly evolving landscape of manufacturing, organizations are continually seeking ways to boost productivity and enhance profitability. One of the most effective strategies is the implementation of manufacturing automation. This approach not only streamlines processes but also significantly reduces operational costs, thereby benefiting the bottom line. By incorporating automated systems, manufacturers can achieve a level of precision and consistency that is challenging to attain through manual labor alone.

As industries face increasing pressure to meet consumer demands and compete in a global market, adopting manufacturing automation becomes imperative. It allows companies to optimize their production flows, minimize human error, and improve overall efficiency. With a well-structured plan for the integration of automated technologies, businesses can position themselves for sustained growth while adapting to the dynamic nature of the manufacturing sector.

In this guide, we will explore effective strategies for implementing manufacturing automation, examining key considerations that lead to maximum efficiency and profitability. From assessing current processes to selecting the right technologies, each step plays a crucial role in transforming your manufacturing operations into a more agile and competitive entity.

Manufacturing automation refers to the use of advanced technologies and software to streamline production processes, significantly enhancing overall operational efficiency. In today's highly competitive industrial landscape, the importance of automation cannot be overstated. By integrating automated systems, manufacturers can reduce human error, minimize labor costs, and optimize resource allocation. This transition not only accelerates production timelines but also improves consistency in product quality, which is crucial for meeting customer expectations and gaining a competitive edge.

Moreover, implementing automation has a profound impact on safety and compliance within manufacturing environments. Automated systems can perform hazardous tasks, thereby reducing the risk of workplace accidents and ensuring a safer environment for employees. Additionally, these technologies can assist in adhering to regulatory standards by providing accurate data and reporting capabilities. Ultimately, the strategic adoption of manufacturing automation empowers organizations to not only boost their profitability but also enhance their sustainability by reducing waste and optimizing energy use throughout the production cycle.

In today’s competitive manufacturing landscape, automating processes can significantly enhance efficiency and profitability. The first step in this journey is to thoroughly assess your current operations. Identifying bottlenecks, redundancies, and labor-intensive tasks provides a clear roadmap to potential automation opportunities. Reports from McKinsey indicate that organizations that implement automation can see productivity gains of 20% to 50%, depending on the complexity of their processes. Conducting a time-and-motion study can be beneficial, allowing manufacturers to pinpoint where automation can replace manual efforts, thus freeing up resources for more strategic initiatives.

Tips for assessing your current processes include gathering data on cycle times, error rates, and employee feedback. Establish key performance indicators (KPIs) for critical tasks to measure their efficiency accurately. This quantitative assessment not only uncovers areas for improvement but also helps in justifying the investment in automation technologies. Additionally, leveraging digital twins and simulation tools can aid in visualizing the impact of changes before implementation, reducing the risk of costly mistakes.

It’s also essential to engage with your workforce during this assessment phase. According to a PwC report, 77% of workers are open to using automation to streamline tasks. This willingness can provide valuable insights, as employees often have firsthand knowledge of pain points in the workflow. By considering their perspectives, you can ensure that the automated systems you choose will genuinely enhance productivity and align with your team's capabilities.

| Process Area | Current Efficiency (%) | Automation Potential (%) | Estimated Cost of Automation ($) | Expected ROI (%) |

|---|---|---|---|---|

| Assembly Line | 75 | 85 | 50000 | 150 |

| Quality Control | 80 | 90 | 30000 | 200 |

| Inventory Management | 70 | 75 | 25000 | 120 |

| Customer Order Processing | 85 | 95 | 40000 | 180 |

| Maintenance Scheduling | 65 | 80 | 20000 | 100 |

Selecting the right automation technologies for your manufacturing needs is crucial for optimizing efficiency and ensuring profitability. The first step in this process is to conduct a thorough assessment of your current manufacturing operations. Identify bottlenecks and inefficiencies, and analyze the specific tasks within your production line that could benefit most from automation. This understanding allows you to pinpoint where automation can yield the greatest return on investment, whether it be in assembly, quality control, or inventory management.

Once you have established the areas needing improvement, consider the various automation technologies available. Robotics, for instance, can offer flexibility and precision, while conveyor systems enhance the flow of materials. Collaborative robots (cobots) can work alongside human operators, increasing productivity without the need for extensive safety measures.

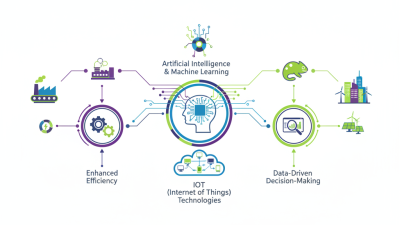

Additionally, integrating smart technologies such as IoT devices can provide real-time data analytics, helping you make informed decisions about your manufacturing processes. Carefully evaluating the scalability and compatibility of these technologies with your existing systems is essential to develop a cohesive automation strategy that aligns with your business goals.

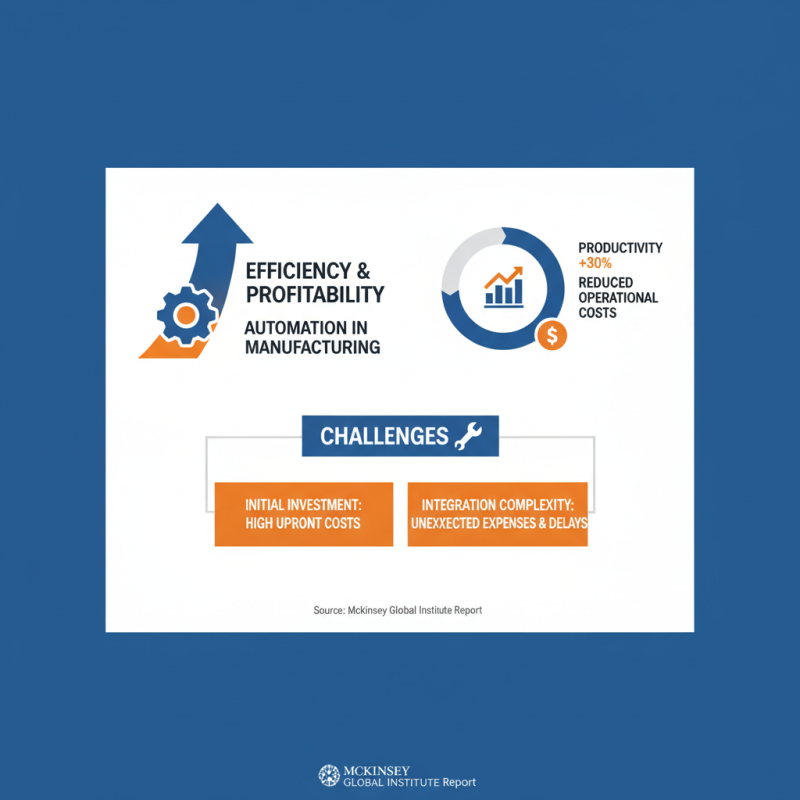

Implementing automation in manufacturing can significantly enhance efficiency and profitability, but it comes with its own set of challenges. A report by the McKinsey Global Institute indicates that automation can improve productivity by up to 30% while reducing operational costs. However, one of the primary hurdles is the initial investment, which can be substantial. Companies often underestimate the costs associated with integrating new technologies into existing workflows, leading to delays and increased expenses.

To effectively implement automation, companies should start by conducting a thorough analysis of their current processes to identify areas where automation would yield the greatest benefits. Creating a clear roadmap that outlines the steps involved—from selecting appropriate technologies to training staff—is crucial. Additionally, engaging all stakeholders early in the process can help alleviate resistance to change and foster a collaborative environment.

**Tip:** Begin with pilot projects in less critical areas to gauge the effectiveness of automation tools before a full-scale rollout.

Moreover, addressing the workforce's concerns about job displacement is vital. Training programs that focus on upskilling employees can not only mitigate fears but also enhance overall productivity. According to a study by Deloitte, companies that invest in retraining their workforce during automation transitions see a 25% increase in employee satisfaction and retention.

**Tip:** Regularly communicate the benefits of automation to your team, stressing how these technologies can augment their roles rather than replace them.

Measuring efficiency and profitability gains from automation integration is crucial for any manufacturing business seeking to optimize its operations. To start, businesses should establish key performance indicators (KPIs) that align with their automation goals. These KPIs may include production speed, waste reduction, and labor costs. Regularly tracking these metrics will provide insights into how automation is impacting your operations financially and operationally. For instance, if production speed increases while labor costs remain stable, companies can ascertain a clear profitability gain from their automation efforts.

Tips: Consider conducting a baseline study before implementing automation to have a clear reference point. This allows for more accurate comparisons post-implementation and helps in understanding the extent of improvements. Additionally, involve your team in the process, as their on-ground insights can highlight areas of inefficiency that automation may address.

Another key factor to measure is the reduction in downtime. With automation, processes become more streamlined, reducing the time machines and employees spend idly. Track the frequency and duration of equipment failures and downtime incidents to calculate the improvement over time. This data will help highlight the cost savings associated with reduced operational interruptions and can further strengthen the case for continued investment in automation.

Tips: Implement a maintenance schedule alongside automation to ensure that machinery operates at optimal efficiency. Regular checks and updates can help minimize unexpected downtime, thus maximizing the benefits of your automation system.