In the realm of process control systems, efficiency is not just a goal; it is a necessity that defines the very foundation of operational excellence. As industries continue to evolve, the pressure to enhance performance while maintaining safety and reliability intensifies. According to Dr. Emily Chen, a leading expert in the field of process automation, "Improving efficiency in process control systems is crucial for maximizing output and minimizing costs, ultimately driving sustainable growth." Her insights highlight the importance of refining processes to achieve superior results.

The integration of advanced technologies, data analytics, and automation strategies can significantly enhance the performance of process control systems. By adopting a systematic approach to optimization, organizations can not only streamline their operations but also ensure that they are equipped to adapt to future challenges. This holistic improvement can lead to greater responsiveness to market demands and improved quality control, paving the way for innovation across various sectors.

As we delve deeper into the strategies for improving efficiency in process control systems, it becomes clear that the path to better performance lies in the convergence of skilled expertise, cutting-edge technology, and a commitment to continuous improvement. The implications of these advancements extend beyond individual organizations, impacting the entire industry landscape and setting new standards for operational success.

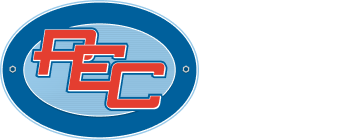

Process control systems play a crucial role in various industries by automating and optimizing production processes. These systems are designed to manage and monitor variables such as temperature, pressure, and flow rates, ensuring that operations run smoothly and efficiently. By utilizing sensors, controllers, and actuators, process control systems can adjust parameters in real-time, leading to improved product quality, reduced waste, and enhanced safety. Understanding the fundamentals of these systems is essential for professionals looking to implement effective strategies to improve performance.

The significance of process control systems extends beyond mere automation. They provide valuable insights through data analytics, enabling organizations to make informed decisions regarding operations. By analyzing performance metrics, businesses can identify bottlenecks and areas for improvement, allowing for timely interventions. Furthermore, with the advent of Industry 4.0, these systems are increasingly integrated with advanced technologies such as artificial intelligence and the Internet of Things (IoT), further enhancing their capabilities. As industries continue to evolve, the importance of robust process control systems in fostering efficiency and driving innovation cannot be overstated.

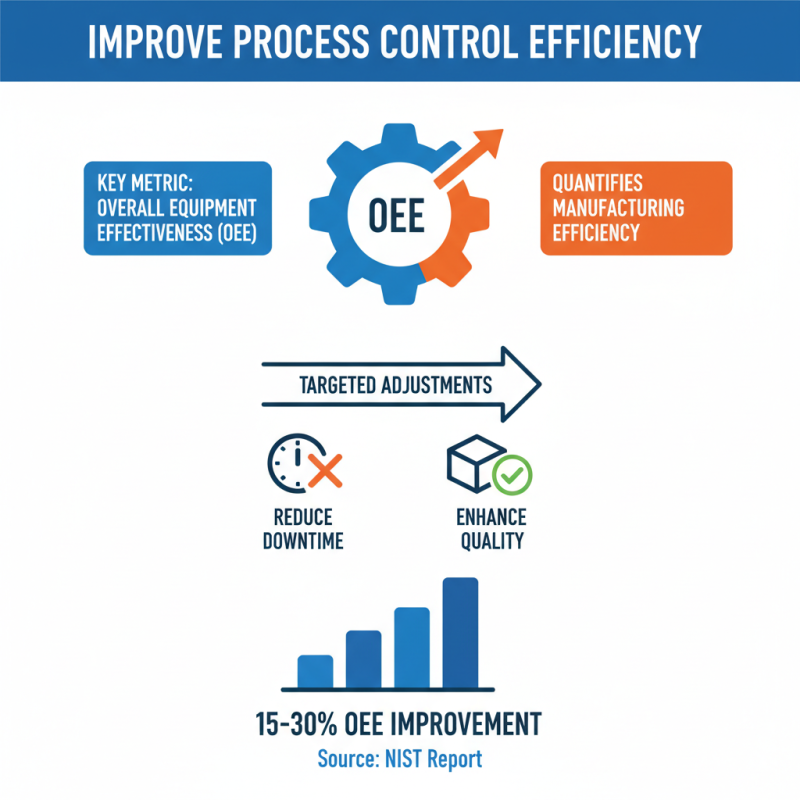

To effectively improve the efficiency in process control systems, it is crucial to focus on measuring key metrics that directly impact performance. One significant metric is the Overall Equipment Effectiveness (OEE), which quantifies the efficiency of manufacturing processes. According to a report by the National Institute of Standards and Technology (NIST), companies can typically improve their OEE by 15-30% through targeted process control adjustments, which reduce downtime and enhance product quality.

Another vital metric is the Process Capability Index (Cp and Cpk). This index measures how well a process can produce outputs within specified limits. A study from the International Society for Automation highlights that maintaining a Cpk of 1.33 or higher can significantly decrease defect rates, leading to a more efficient production cycle. Additionally, monitoring energy consumption per unit of output provides insights into operational efficiency, with the U.S. Department of Energy noting that firms optimizing energy usage can reduce costs by up to 30%, further underscoring the importance of these metrics.

By continuously analyzing these key performance indicators, organizations can implement strategic improvements in their process control systems that lead to enhanced efficiency and overall performance. Emphasizing data-driven decisions based on these metrics enables companies to identify bottlenecks, streamline operations, and ultimately achieve better productivity outcomes.

The integration of advanced technologies in process control systems is crucial for optimizing performance and enhancing overall efficiency. Modern control systems can leverage innovations such as artificial intelligence, machine learning, and the Internet of Things (IoT) to create adaptive environments that respond in real-time to fluctuations in process parameters. Utilizing AI-driven algorithms allows for predictive analytics, enabling system operators to anticipate and mitigate potential issues before they escalate, thereby minimizing downtime and resource wastage.

Moreover, incorporating advanced sensor technologies and data analytics tools provides deeper insight into operational metrics. These tools can facilitate continuous monitoring of equipment and processes, ensuring that any deviations from optimal performance are promptly addressed. By enabling a more granular understanding of system behavior, organizations can fine-tune control strategies, leading to improved stability, efficiency, and product quality. Ultimately, embracing these advanced technologies not only enhances control system performance but also fosters a culture of innovation that can drive further advancements in process management.

This chart illustrates the efficiency percentage of process control systems before and after implementing advanced technologies. A significant improvement can be noted, demonstrating the positive impact of enhanced control system performance.

Minimizing downtime is crucial for process control systems to enhance overall efficiency and productivity. According to a recent report by the International Society of Automation, companies that implement predictive maintenance can reduce equipment failures by 30% to 50%. This shift from reactive to predictive maintenance allows organizations to schedule repairs during non-peak hours, effectively minimizing interruptions in the production line. By leveraging real-time data analytics, organizations can monitor equipment health and preemptively address potential issues, aligning maintenance schedules with actual operational needs.

In addition to adopting predictive maintenance, optimizing workflow processes is essential for maximizing productivity. The World Economic Forum's research indicates that streamlining operational processes can lead to productivity increases of up to 25%. Techniques such as automating repetitive tasks and implementing continuous improvement methodologies, like Lean and Six Sigma, help remove inefficiencies in workflows. Furthermore, organizations that foster a culture of innovation and empower employees to identify process improvements often see not only increased output but also enhanced employee engagement, which can further contribute to a robust operational performance. By focusing on these strategies, organizations can effectively enhance their process control systems and achieve significant productivity gains.

| Strategy | Description | Expected Impact (%) | Implementation Time (Weeks) |

|---|---|---|---|

| Automated Monitoring | Implement sensors and systems for real-time data collection and monitoring. | 25 | 6 |

| Predictive Maintenance | Use data analytics to predict equipment failures and schedule maintenance. | 20 | 8 |

| Training Programs | Enhance employee skills through regular training on new technologies and processes. | 15 | 4 |

| Lean Manufacturing | Adopt lean principles to eliminate waste and improve workflow efficiency. | 30 | 12 |

| Process Optimization | Regularly analyze and adjust processes to enhance productivity and reduce cycle time. | 22 | 10 |

In the pursuit of enhanced performance within process control systems, several case studies exemplify successful efficiency improvements. One notable case involves the energy sector, where automation and real-time monitoring were implemented to optimize the control of power generation processes. By utilizing advanced algorithms, operators were able to identify inefficiencies in energy distribution and consumption, leading to a substantial reduction in operational costs and increased output. The integration of predictive maintenance further ensured that equipment downtime was minimized, keeping the production cycle uninterrupted.

Another significant case study can be found in the chemical manufacturing industry. Here, a firm undertook a comprehensive review of its control strategies and processes. By employing data analytics and machine learning techniques, the company was able to pinpoint bottlenecks and redundancies within their workflow. The subsequent redesign of their process control framework not only streamlined operations but also improved product quality and consistency. These changes resulted in a remarkable increase in production rates, highlighting the critical role of technology and data-driven insights in achieving process efficiency. Through these real-world examples, it is evident that a focused approach to improving efficiency in process control systems can lead to substantial performance gains across various sectors.