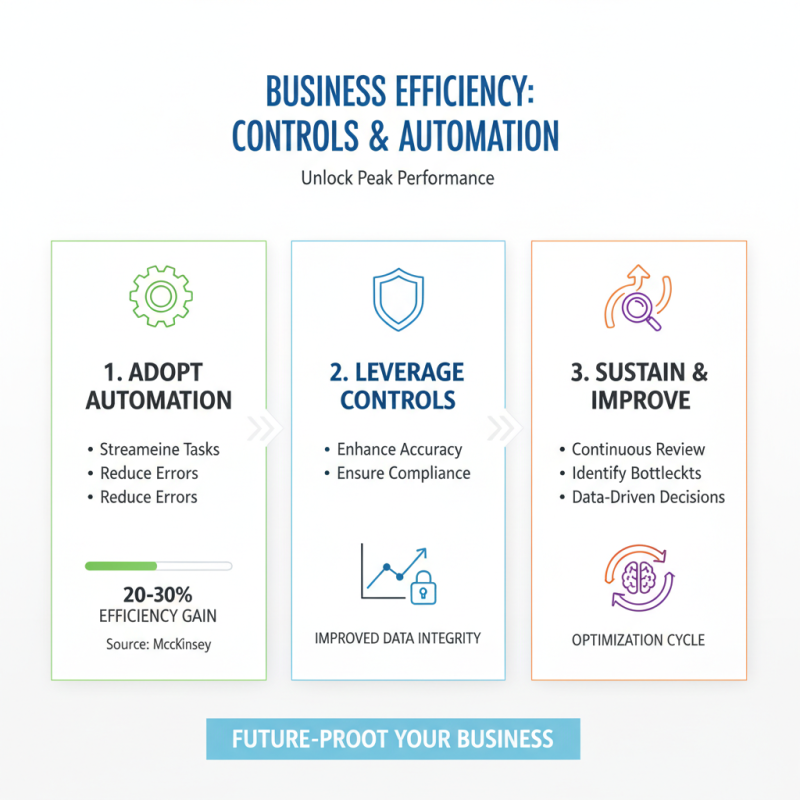

In today's rapidly evolving industrial landscape, the integration of controls and automation has become paramount for enhancing efficiency and productivity. According to a report by McKinsey & Company, companies that effectively leverage automation technologies can boost their operational productivity by nearly 30%. This insightful data underscores the critical role automation plays in optimizing processes and reducing operational costs.

As automation expert Dr. Emily Harmon remarks, “The future of manufacturing lies in the intelligent use of controls and automation to drive unparalleled efficiency.” This sentiment reflects the growing recognition within the industry that robust control systems not only streamline operations but also facilitate better resource management. By employing advanced automation technologies, businesses can minimize human error, accelerate production timelines, and ultimately achieve higher output with fewer resources.

In conclusion, the synergy between controls and automation represents a transformative opportunity for organizations to enhance their competitive edge. As industries continue to explore innovative automation solutions, the benefits will be increasingly evident, paving the way for a more efficient and productive future.

In today's fast-paced business environment, the integration of controls and automation is essential for enhancing efficiency and productivity. According to a report by McKinsey & Company, organizations that have implemented automation technologies report a 20-30% increase in productivity. This substantial gain underscores the critical role that automation plays in streamlining operations and reducing the time needed for routine tasks. By minimizing human error and increasing consistency, businesses can allocate resources more effectively, driving growth and profitability.

Incorporating robust control systems is equally essential. A study from Deloitte highlights that companies with strong internal controls can reduce operational risks, improve compliance, and enhance overall performance metrics. Such systems empower businesses to monitor real-time data, thereby allowing for quicker decision-making processes. The synergy of automation and controls not only fosters a proactive approach to managing operations but also creates a culture of continuous improvement.

Tips for successful implementation include starting small with automating repetitive tasks, such as data entry and reporting processes. This allows teams to adapt gradually to new technologies without overwhelming them. Additionally, invest in training programs to ensure your staff is fully equipped to leverage new tools effectively. Lastly, regularly evaluate the effectiveness of your controls and automation solutions to fine-tune processes and maximize their impact on your organization's efficiency and productivity.

Identifying areas for automation is a crucial step in enhancing operational efficiency within any organization. By closely examining routine tasks and workflows, companies can pinpoint processes that are repetitive and time-consuming. For instance, data entry, report generation, and inventory management are often ripe for automation. Automation not only accelerates these processes but also minimizes the risk of human error, leading to more accurate outcomes and resource allocation.

Moreover, engaging employees in the identification of automation opportunities can yield valuable insights. Employees on the front lines frequently encounter inefficiencies that management may overlook. By soliciting their input, organizations can uncover specific bottlenecks or redundancies that, once addressed through automation, can streamline operations further. The implementation of automation tools tailored to these identified areas also fosters a more agile work environment, allowing teams to focus on higher-value tasks that drive innovation and growth.

Implementing control systems is a crucial step to streamline processes within any organization. By establishing clear protocols and automated workflows, businesses can significantly reduce manual errors and enhance operational reliability. Control systems create a structured environment where tasks are consistently executed, allowing team members to focus on value-added activities rather than getting bogged down in repetitive, time-consuming duties. The integration of automation into these control processes not only speeds up operations but also provides real-time data for informed decision-making.

Moreover, effective control systems facilitate transparency and accountability across departments. By defining roles and establishing measurable outcomes, organizations can better track performance and identify areas for improvement. Automation tools can generate insights from data collected during processes, leading to continuous adjustments and refinements. This iterative approach enables businesses to respond swiftly to changes, optimize resource allocation, and maintain a competitive edge in the market. Ultimately, the thoughtful implementation of control systems creates a framework for sustained efficiency and productivity, empowering teams to achieve their objectives more effectively.

Measuring the impact of automation on productivity metrics is crucial for organizations aiming to enhance efficiency. To accurately assess this impact, businesses can start by identifying key performance indicators (KPIs) that reflect productivity levels before and after implementing automation solutions. Common metrics include output rate, cycle time, and error rates. By establishing a baseline for these metrics, organizations can track improvements and calculate the return on investment for automation technologies.

Furthermore, qualitative measurements, such as employee satisfaction and engagement, can provide additional insights into the effects of automation on productivity. While automation often leads to increased output, it can also relieve employees from repetitive tasks, allowing them to focus on higher-value activities. Collecting feedback from staff regarding their workload and job satisfaction can yield valuable data to assess the broader impact of automation. Combining quantitative and qualitative metrics offers a comprehensive view of how automation not only enhances efficiency but also contributes to a more engaged and motivated workforce.

In today's fast-paced business environment, leveraging controls and automation has become essential for organizations aiming to enhance efficiency and productivity. A study by McKinsey indicates that companies can improve operational efficiency by up to 20-30% through the adoption of automation technologies. However, simply integrating these technologies is not enough; businesses must also focus on sustaining efficiency through ongoing improvement practices. This involves continuously reviewing processes, identifying bottlenecks, and utilizing data analytics to make informed decisions.

Best practices for sustaining efficiency include fostering a culture of continuous improvement among employees. According to a report by the Harvard Business Review, organizations that encourage employee engagement in process optimization activities see a significant increase in productivity, averaging around 15%. Additionally, implementing regular training and feedback loops helps staff adapt to new tools and methods, ensuring that efficiency gains are maintained. The integration of automated feedback systems can also facilitate real-time adjustments, making it easier for teams to respond to dynamic market conditions and evolving customer needs. By prioritizing these strategies, businesses can create a resilient framework that not only drives efficiency but also positions them for long-term success.