In the rapidly evolving landscape of industrial operations, mastering process control training is more crucial than ever for achieving efficiency and reliability in production systems. As organizations strive to optimize their processes, the implementation of comprehensive training programs empowers employees with the knowledge and skills necessary to monitor, regulate, and improve operational performance. This article delves into the vital components and methodologies that constitute effective process control training, highlighting its significance in fostering a culture of continuous improvement within organizations.

The modern industry demands a workforce that is not only adept at handling routine tasks but is also equipped to make informed decisions based on real-time data and analytics. By focusing on key principles of process control training, including system dynamics, feedback loops, and control strategies, organizations can ensure that their teams are prepared to tackle challenges head-on. This proactive approach not only enhances overall productivity but also mitigates risks associated with operational failures.

Ultimately, the mastery of process control training is a strategic investment that benefits both personnel and the enterprise as a whole. By committing to structured educational initiatives, companies can unlock the full potential of their operational processes, leading to improved performance outcomes and a robust competitive edge in the market.

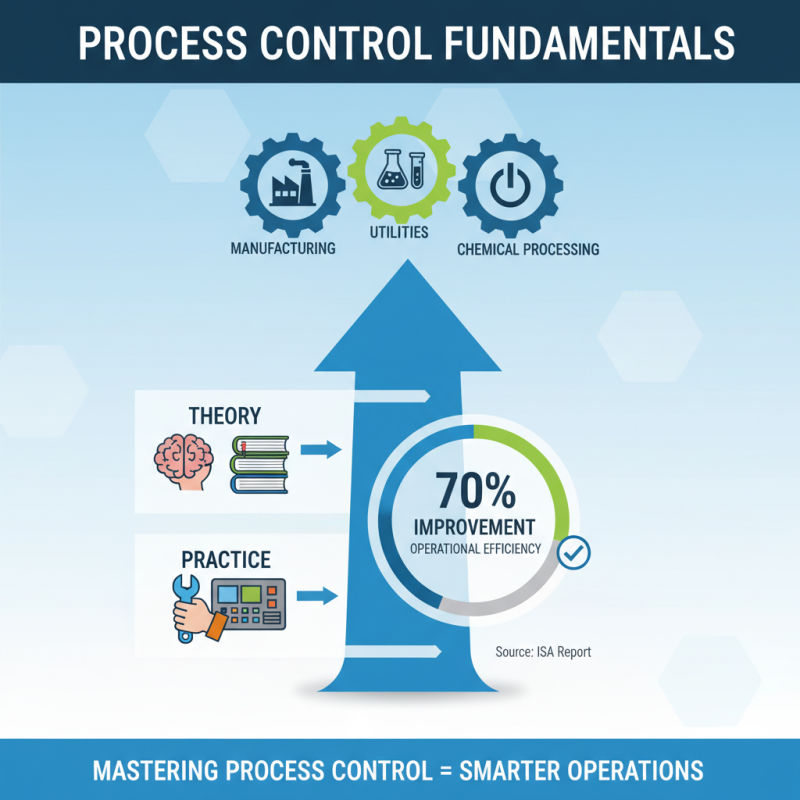

Understanding the fundamentals of process control is crucial for effective operations in various industries, including manufacturing, chemical processing, and utilities. According to a report by the International Society of Automation, around 70% of companies that implement effective process control strategies see a significant improvement in operational efficiency. This highlights the importance of mastering both the theoretical and practical aspects of process control training.

Process control encompasses the monitoring and management of process variables to ensure desired outcomes are consistently met. Key elements include the understanding of control loops, feedback mechanisms, and the role of sensors and actuators. A study by the American Institute of Chemical Engineers found that organizations with a robust understanding of process dynamics and control strategies are 50% more likely to achieve their production targets on time. This clearly indicates that a sound foundational knowledge can lead to substantial operational gains, positioning companies competitively in the market.

Additionally, training in process control prepares teams to handle real-time data effectively, making decisions based on accurate measurements and reducing waste. The National Association of Manufacturers reports that industries that invest in advanced process control training programs can reduce production costs by up to 20%. Thus, emphasizing a strong foundation in process control not only enhances operational efficiency but also fosters innovation by enabling teams to adapt to changing market demands swiftly.

Effective process control training is built on a solid understanding of key concepts and terminology that are fundamental to the field. At the heart of process control is the notion of feedback systems, where the output of a process is monitored and adjusted to achieve desired performance levels. Terms such as "set point," "control loop," and "disturbance" are essential in describing how processes are regulated. A set point represents the target value that the system aims to maintain, while control loops consist of sensors, controllers, and actuators working together to modulate the process variables and respond to any disturbances that may affect performance.

In addition to these key terms, understanding the various types of control strategies is crucial for mastering process control. Techniques such as proportional-integral-derivative (PID) control provide a framework for calculating the necessary adjustments to maintain stability and improve responsiveness. Familiarity with terminology related to process dynamics, such as "time constant" and "gain," helps trainees appreciate how systems react over time and how to optimize their performance.

In addition to these key terms, understanding the various types of control strategies is crucial for mastering process control. Techniques such as proportional-integral-derivative (PID) control provide a framework for calculating the necessary adjustments to maintain stability and improve responsiveness. Familiarity with terminology related to process dynamics, such as "time constant" and "gain," helps trainees appreciate how systems react over time and how to optimize their performance.

By integrating these concepts into training curricula, learners can develop a comprehensive skill set that enables them to tackle real-world operational challenges with confidence and precision.

Mastering process control training requires a structured approach to effectively implement various techniques. The first step is to gain a solid understanding of the fundamental concepts of process control. This involves studying the principles of feedback control loops, understanding controller types, and familiarizing oneself with key performance indicators. Engaging in hands-on activities, such as simulations and real-world problem-solving, can bolster comprehension significantly. It's critical to create a learning environment where inquiry is encouraged, enabling learners to ask questions and explore solutions collaboratively.

The next focus should be on practical application through step-by-step methodologies. This includes defining clear objectives for each training module, ensuring all participants understand these goals. Structured scenarios that mimic real-life conditions can help trainees practice decision-making and process adjustments dynamically. Incorporating feedback mechanisms, where trainees can receive constructive evaluation, is also essential. Regular assessment and iteration of training techniques based on participant performance and feedback can catalyze continuous improvement, enhancing overall operational efficiency and fostering a culture of excellence in process control.

Effective process control training is essential for optimizing operations in any industry. To implement a successful training program, it’s vital to start by assessing the specific needs of your organization. This means identifying key areas where process control can enhance efficiency and safety. Collaboration with experienced professionals can help you tailor your training content to address these specific goals. Providing customized resources, such as hands-on simulations and case studies, can significantly improve trainees' engagement and understanding.

Tips: Consider integrating interactive learning methods into your program. Utilizing simulations or gamified learning experiences encourages participation and retention of information. Regularly update training materials to reflect the latest industry advancements and best practices, ensuring your team is always equipped with the most relevant knowledge.

Additionally, fostering a culture of continuous improvement within your organization can greatly enhance the effectiveness of process control training. Encourage team members to share insights and experiences from their training; this exchange of knowledge can lead to collective growth. Implementing regular feedback loops can also help refine your training initiatives, making them more effective over time and ensuring they meet evolving operational demands.

The impact of process control on operational efficiency is profound, as effective process control systems play a crucial role in optimizing production environments. By implementing precise measurement and control techniques, organizations can minimize variations in their processes, leading to consistent product quality and reduced waste. This reliability not only enhances customer satisfaction but also drives down operational costs, allowing businesses to allocate resources more effectively.

Moreover, the integration of real-time data analysis within process control frameworks empowers organizations to make informed decisions swiftly. By continuously monitoring key performance indicators, companies can proactively identify inefficiencies and implement corrective actions before small issues escalate into significant problems. This agility in operations ensures that companies remain competitive in a fast-paced market, where operational excellence is vital for sustainability and growth. Consequently, investing in process control training becomes essential for personnel, equipping them with the skills to leverage technology and data in driving efficiency across all facets of operations.

| Training Program | Duration (Days) | Cost (USD) | Employee Satisfaction (%) | Operational Efficiency Improvement (%) |

|---|---|---|---|---|

| Basic Process Control | 5 | 1,200 | 85 | 10 |

| Advanced Process Techniques | 7 | 1,800 | 90 | 15 |

| Hands-On Process Simulation | 4 | 900 | 88 | 12 |

| Process Optimization Strategies | 6 | 1,500 | 92 | 20 |

| Lean Process Control | 5 | 1,100 | 87 | 9 |