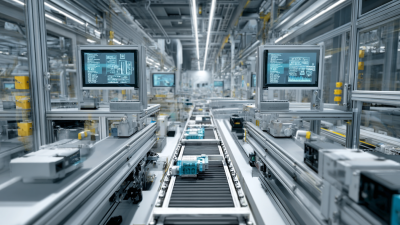

In today's fast-paced industrial environment, optimizing manufacturing process control systems is paramount to achieving maximum efficiency. As technology continues to evolve, the integration of smart systems and automation plays a crucial role in enhancing production workflows. According to Dr. Emily Carter, a leading expert in manufacturing systems engineering, "The key to optimizing manufacturing process control systems lies in the seamless collaboration between cutting-edge technology and skilled human oversight." This highlights the essential balance that must be struck between automated processes and the value of human intelligence in decision-making.

Manufacturing process control systems serve as the backbone of modern production facilities, ensuring that quality, speed, and consistency are maintained throughout the manufacturing journey. By focusing on the intricacies of these systems, companies can identify areas for improvement and implement strategies that not only reduce waste and downtime but also enhance output. This article will explore various strategies and best practices for optimizing these systems, looking at how real-time data analytics, advanced control algorithms, and continuous feedback loops can transform the efficiency of manufacturing operations. Ultimately, the goal is to harness the full potential of manufacturing process control systems to drive productivity and innovation in an increasingly competitive marketplace.

Identifying key performance indicators (KPIs) is crucial for optimizing manufacturing process control systems. KPIs serve as measurable values that reflect the success and efficiency of various manufacturing processes. By tracking these indicators, manufacturers can gain valuable insights into productivity, quality, and operational effectiveness, enabling them to make informed decisions that drive continuous improvement. Common KPIs include production rate, yield, downtime, and defect rates, which offer a comprehensive view of the manufacturing landscape.

To effectively implement KPIs, organizations should first align them with their strategic objectives. This alignment ensures that the metrics being tracked not only provide insights into operational performance but also reinforce the broader goals of the organization. Furthermore, it is essential to regularly review and adjust the KPIs based on changing market conditions and technological advancements. By establishing a feedback loop that incorporates these adjustments, manufacturers can sustain a culture of agility and responsiveness, ultimately leading to maximum efficiency in their processes.

Assessing current manufacturing process control systems is a critical step towards optimizing efficiency in production environments. By conducting a thorough evaluation of existing systems, manufacturers can identify gaps and areas for improvement. This assessment typically involves analyzing the performance metrics of the control systems, such as response times, accuracy, and reliability. It also includes evaluating the integration of technology and software solutions that enable real-time monitoring and data collection, which are essential for informed decision-making.

Additionally, understanding user interactions and operational workflows is vital in this assessment process. Engaging with operators and engineers provides valuable insights into practical challenges faced on the shop floor. This feedback can highlight issues such as usability problems with the control interfaces or inefficiencies in communication between different systems. By addressing these concerns, manufacturers can redevelop their process control systems to enhance user experience and streamline operations, ultimately leading to increased productivity and reduced operational costs.

The implementation of advanced technologies in process control significantly enhances the manufacturing process by optimizing efficiency, accuracy, and overall productivity. Automation tools such as AI-driven analytics and machine learning models enable manufacturers to predict equipment failures and optimize maintenance schedules. By leveraging real-time data, companies can make informed decisions that streamline operations and reduce costs. The integration of IoT devices further allows for seamless communication between machines, facilitating a more responsive manufacturing environment.

Tips: To maximize the advantages of advanced technologies, start by assessing your current process control systems. Identify bottlenecks and areas in need of improvement, then prioritize the deployment of specific technologies that address these issues. Furthermore, ensure your team receives comprehensive training on using new technologies to enhance adoption and proficiency.

Additionally, embracing data analytics helps in refining process control. By analyzing historical data, manufacturers can establish performance benchmarks and identify trends that inform adjustments to production processes. This proactive approach not only improves efficiency but also enhances product quality, ensuring consistency and customer satisfaction.

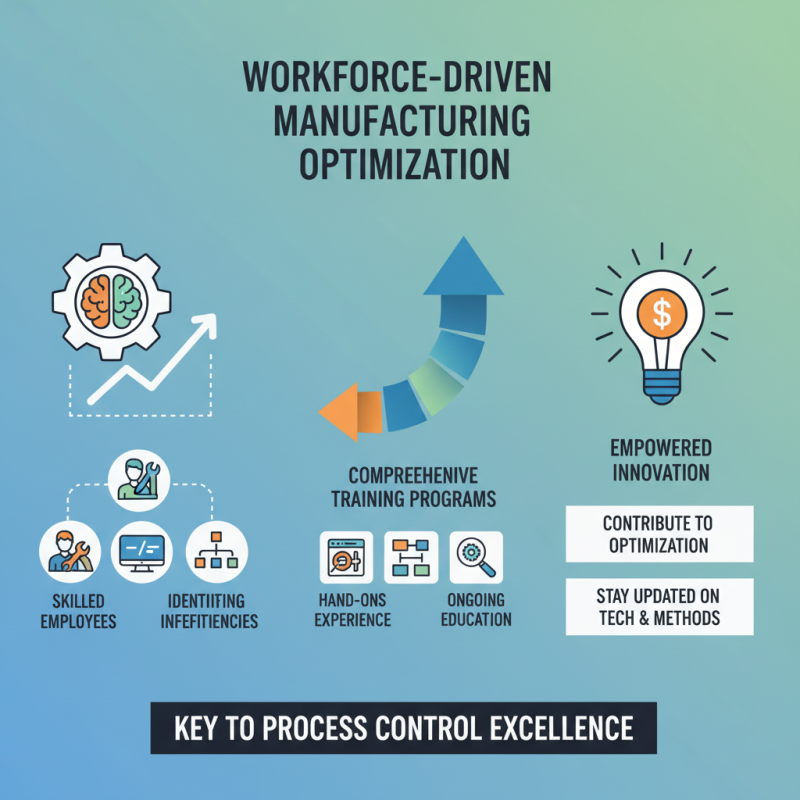

The successful optimization of manufacturing process control systems greatly relies on the active training and involvement of the workforce. Skilled employees who understand the intricacies of the systems they operate are crucial in identifying inefficiencies and suggesting improvements. By providing comprehensive training programs that delve into various aspects of process control systems, manufacturers empower their workforce to contribute to optimization efforts. These programs should include hands-on experiences, simulations, and ongoing education to ensure that employees remain well-versed in the latest technologies and methodologies.

Involving the workforce in optimization efforts not only enhances their skills but also fosters a culture of collaboration and innovation. When employees feel their input is valued, they are more likely to take initiative in identifying potential areas for improvement. Regular feedback sessions can serve as a platform for sharing ideas, discussing challenges, and brainstorm solutions collaboratively. By creating an environment where every team member feels responsible for process efficiency, manufacturers can tap into the collective knowledge and creativity of their workforce, leading to more sustainable and effective optimization strategies.

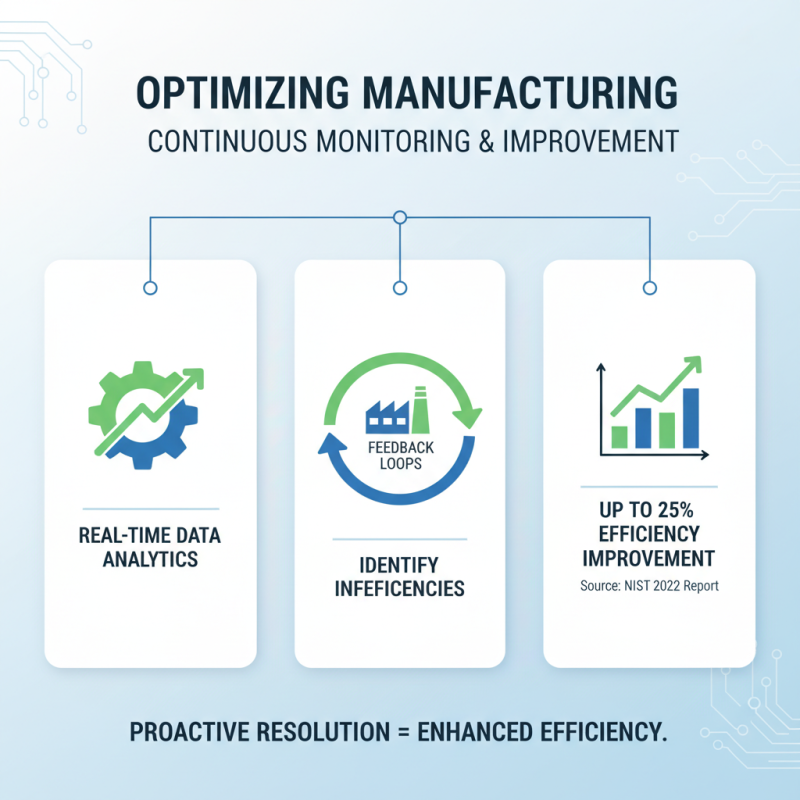

Continuous monitoring and improvement strategies are crucial for optimizing manufacturing process control systems to enhance efficiency. By implementing real-time data analytics and feedback loops, manufacturers can identify inefficiencies and make data-driven adjustments swiftly. According to a 2022 report by the National Institute of Standards and Technology (NIST), companies that employed continuous monitoring saw efficiency improvements of up to 25%. This suggests that uninterrupted observation of manufacturing processes not only uncovers latent issues but also facilitates the proactive resolution of potential disruptions before they escalate.

Moreover, adopting lean manufacturing principles, which focus on minimizing waste without sacrificing productivity, can significantly complement continuous monitoring efforts. A survey by the Lean Enterprise Institute indicated that organizations applying these principles alongside monitoring measures reported a 30% reduction in cycle times and a 20% increase in on-time delivery metrics. By fostering a culture of continuous improvement and utilizing advanced technologies such as IoT devices and machine learning algorithms, manufacturers can optimize their operations, reduce costs, and ultimately deliver higher value to their customers.