In today's rapidly evolving industrial landscape, the optimization of process control systems is paramount for organizations striving for maximum efficiency and reliability. According to a recent report by the International Society for Automation (ISA), industries that implement advanced process control systems can achieve up to a 30% increase in operational efficiency while simultaneously reducing unplanned downtimes by 25%. These statistics underscore the critical role that effective process control strategies play in enhancing productivity and minimizing operational risks.

Dr. Emily Johnson, a prominent expert in industrial automation, emphasizes the importance of integrated process control systems, stating, "The key to achieving operational excellence lies in leveraging data-driven insights within process control systems to address inefficiencies proactively." Her insights highlight that the fusion of innovative technologies, such as machine learning and real-time monitoring, can significantly enhance the decision-making capabilities of process control systems.

As industries continue to face challenges such as fluctuating market demands and increasing competitiveness, optimizing process control systems not only serves as a means to streamline operations but also as a strategic advantage in securing a sustainable future. The focus on refinement and continuous improvement in process control practices is more crucial now than ever for achieving lasting reliability and efficiency.

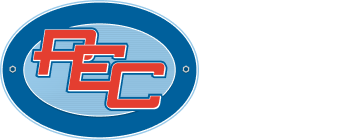

Process control systems are essential in numerous industries to maintain consistent and efficient operations. Understanding these systems requires knowledge of their core components, which typically include sensors, controllers, actuators, and the associated algorithms that drive them. Sensors gather real-time data about variables such as temperature, pressure, and flow rates, while controllers process this data to make informed decisions by comparing current values to desired set points. This feedback loop is critical to automated processes, as it enables quick adjustments to maintain optimal operating conditions.

Actuators play a vital role in conveying the commands from the controllers to the physical systems. They perform necessary actions—such as opening a valve or adjusting a motor speed—based on the controller's output. This interaction ensures that the process remains within designated parameters, ultimately leading to improved efficiency and reliability. Furthermore, system architecture, including the arrangement of these components and the communication protocols used, can significantly impact overall performance. By optimizing the integration and functioning of these elements, industries can achieve a higher level of operational reliability and efficiency, resulting in reduced downtime and minimized resource waste.

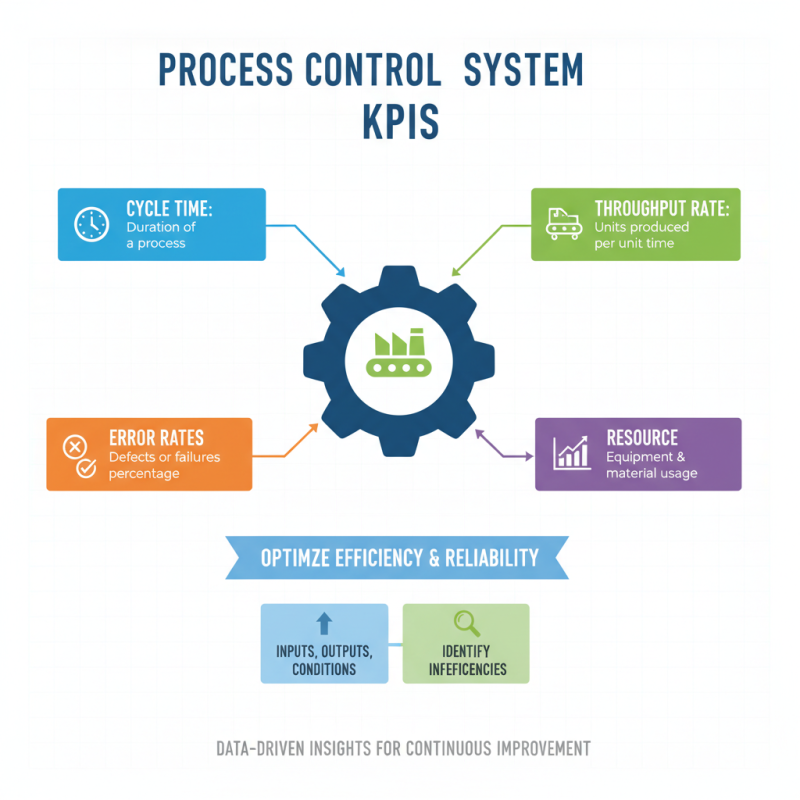

Identifying key performance indicators (KPIs) is essential for optimizing process control systems to ensure maximum efficiency and reliability. These metrics serve as quantifiable measures that can reflect how well a system is performing concerning its goals. To pinpoint the most relevant KPIs, it is crucial to consider data related to process inputs, outputs, and operational conditions. Common KPIs might include cycle time, throughput rate, error rates, and resource utilization, each offering insights that help in identifying inefficiencies or potential failure points.

Once KPIs are established, continuous monitoring and analysis play a vital role in enhancing process performance. By leveraging real-time data, organizations can proactively address deviations from desired performance levels, allowing for timely interventions. Adapting process control algorithms based on KPI feedback can further streamline operations, ensuring that systems not only maintain efficiency but also enhance reliability. In this way, organizations build a resilient framework that supports sustainable performance improvements, ultimately driving enhanced productivity and operational success.

Implementing advanced control strategies is pivotal for optimizing process control systems, particularly in industries striving for greater efficiency and reliability. Research indicates that sophisticated control algorithms, such as Model Predictive Control (MPC) and Adaptive Control, can reduce operational costs by up to 25% while simultaneously enhancing product quality. MPC, for instance, enables operators to anticipate future events and adjust control actions preemptively, which not only improves reaction times but also minimizes the risk of process deviations.

Moreover, the integration of data analytics and machine learning into control systems has revolutionized operational methodologies. A report from McKinsey & Company estimates that companies employing advanced analytics for process control can unlock up to $250 billion in value annually across various sectors. By utilizing real-time data and predictive modeling, organizations can identify inefficiencies, optimize resource allocation, and ultimately drive down energy consumption. This transition towards digitalization ensures that process control systems not only function reliably but also contribute significantly to sustainability efforts, addressing both financial and environmental goals effectively.

| Control Strategy | Efficiency Gain (%) | Reliability (%) | Implementation Time (months) | Cost Reduction (%) |

|---|---|---|---|---|

| Model Predictive Control | 15 | 98 | 6 | 10 |

| Fuzzy Logic Control | 12 | 95 | 5 | 8 |

| PID Control with Tuning | 10 | 90 | 3 | 5 |

| Adaptive Control | 20 | 97 | 8 | 12 |

| Sliding Mode Control | 18 | 96 | 7 | 11 |

Periodic maintenance and upgrading are crucial for ensuring that process control systems operate at peak efficiency and reliability. Regular maintenance routines help identify and rectify minor issues before they escalate into significant problems, which can lead to system downtime and operational inefficiencies. It is essential to establish a maintenance schedule that includes regular inspections, calibration of instruments, and testing of control algorithms. By doing so, operators can maintain optimal performance levels and extend the lifespan of their equipment.

Upgrading control systems not only enhances functionality but also incorporates the latest technological advancements, which can lead to improved data analytics and process optimization. This is particularly critical as industries face increasing demands for productivity and precision. Upgrades may involve software updates, integration of new sensors, or the adoption of advanced control strategies. These enhancements can significantly boost the system's responsiveness and adaptability, thus ensuring reliability in various operating conditions.

Emphasizing both periodic maintenance and timely upgrades helps organizations stay ahead of potential failures and meet evolving operational requirements efficiently.

Training and skill development for process control personnel are critical for ensuring efficient and reliable operations within any organization. A well-structured training program not only equips employees with the necessary technical skills but also empowers them to understand the complexities of process control systems. By emphasizing hands-on training, simulations, and real-world problem-solving scenarios, organizations can cultivate a workforce that is adept at managing and optimizing these systems.

Moreover, continuous learning and development should be an integral part of the culture within process control environments. Regular workshops, webinars, and certifications keep personnel updated on the latest technologies and methodologies in process control. This proactive approach not only enhances individual competencies but also fosters teamwork and collaboration among staff, leading to improved overall performance. As personnel refine their skills, they become more capable of anticipating issues, implementing corrective measures, and contributing to a more resilient and efficient operational framework.