In today's fast-paced manufacturing world, effective process control manufacturing techniques are essential. These methods help streamline production while maintaining high quality. Companies strive for efficiency. They want to reduce waste and enhance output. However, not all techniques work perfectly in every environment. Some require adaptation, while others may become outdated.

Understanding the top process control manufacturing techniques can provide a competitive edge. Techniques such as Statistical Process Control (SPC) and Lean Manufacturing can drastically improve workflow. Investing in the right technology is crucial. Yet, some companies struggle with implementation. They may face resistance from employees or lack proper training.

Additionally, continuous monitoring and feedback loops are vital. They help pinpoint areas for improvement. Failing to adapt can lead to stagnation. As industries evolve, so must the techniques and tools used. Embracing change is essential for success. The following exploration of key techniques will shed light on what can drive effective process control manufacturing.

Process control manufacturing is essential for efficiency and quality. Knowing the top techniques can boost productivity and enhance quality control. According to a recent industry report, implementing advanced control strategies can reduce production costs by up to 30%. This statistic highlights the importance of effective process management.

One key technique is Statistical Process Control (SPC). It uses statistical methods to monitor and control processes. SPC helps identify variations, ensuring products meet specifications. Businesses that adopt SPC notice up to a 25% reduction in waste.

Another approach is Batch Process Control, which manages production in batches. This method is ideal for industries like food and pharmaceuticals where consistency is crucial.

Tips: Invest in training your team. Skilled operators can make informed decisions during production. Regularly review your process performance. Adjustments may be needed. Analyze data consistently for patterns. Ignoring data can lead to significant issues. Be open to refining your techniques; the industry evolves constantly. Adapting to new technologies can greatly impact your success.

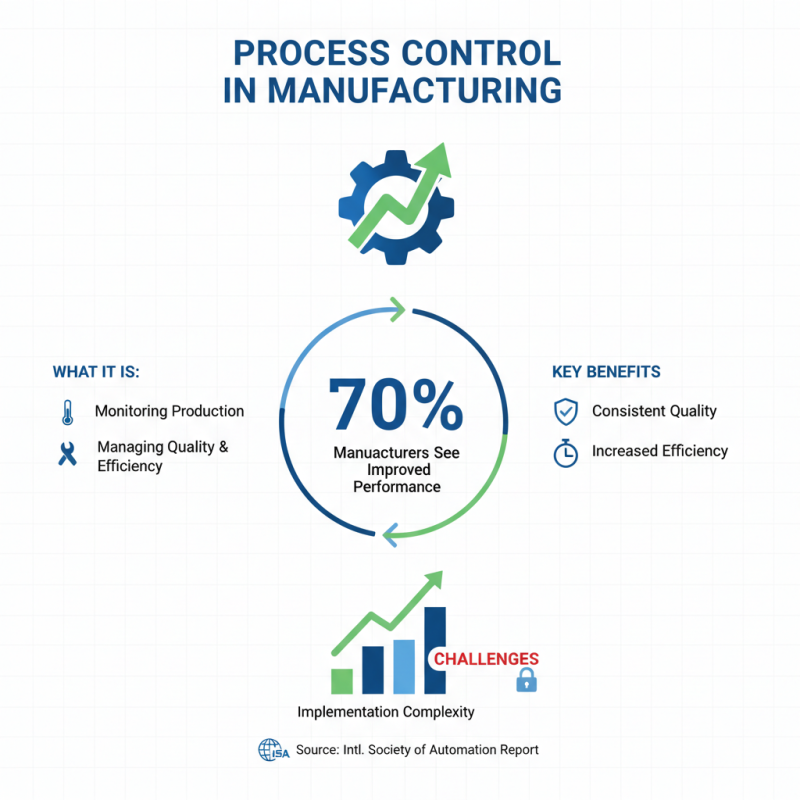

Process control is a critical aspect of modern manufacturing environments. It involves monitoring and managing production processes to ensure consistent quality and efficiency. According to a report from the International Society for Automation, 70% of manufacturers see improved performance through process control techniques. However, achieving this is not always straightforward.

Many companies struggle with integrating advanced technologies into their workflows. For instance, utilizing real-time data analytics can enhance decision-making, yet many firms face challenges in data accuracy and system interoperability. The challenge lies not just in technology adoption but also in cultural resistance within organizations. In some cases, employees may resist changes due to fear of job loss or a lack of understanding of new systems.

Moreover, there’s a growing need for skilled professionals who understand process control systems. A survey by the Manufacturing Institute indicates that 2 million manufacturing jobs may go unfilled due to the skills gap. This highlights an urgent need for training and education in the field. The path forward requires investment in workforce development alongside technological upgrades. Engaging employees and bridging the skills gap is essential for future success in process control within manufacturing.

Automation plays a crucial role in process control. It enhances operational efficiency in the manufacturing sector. According to a report by McKinsey, companies that implement automation can see productivity increases of up to 30%. This shift allows manufacturers to optimize processes in real-time, managing resources more effectively.

Despite its advantages, automation is not always a smooth transition. Implementing new technologies can present challenges. Workers may feel uncertain about their roles as machines take over manual tasks. It is essential to address these concerns and provide adequate training. A survey by Deloitte revealed that 58% of employees fear job displacement due to automation.

The integration of automation can lead to improved quality and reduced waste. Industry data shows that automating process controls can decrease production errors by 50%. However, companies must find the right balance between technology and human expertise. Fully relying on machines may overlook critical insights from experienced workers. Striving for harmony between automation and human input can enhance overall efficiency and innovation.

This chart illustrates the popularity of various process control manufacturing techniques, showcasing their significance in modern automation and operational efficiency.

In process control manufacturing, effective techniques are crucial for optimizing systems. PID control and feedforward control are two fundamental methodologies. PID control, which stands for Proportional-Integral-Derivative, adjusts the process output based on the error between a desired setpoint and the actual process variable. According to industry reports, about 70% of control loops in manufacturing use PID control. This technique is valued for its reliability and simplicity, but it can struggle with complex systems. Delays or non-linear characteristics can lead to performance issues.

Feedforward control complements PID by anticipating disturbances. It uses process measurement data to adjust control actions proactively. This method can enhance system responsiveness significantly. Research shows that implementations can reduce error by up to 30% compared to PID-only strategies. However, the design of a feedforward control system can be challenging due to the need for precise modeling.

Tip: Always validate your control strategies with simulation before full implementation. This provides insight into potential system behavior without risking production quality. Another point to consider is the importance of regular tuning. Process changes can shift dynamics, making your initial settings less effective over time. Regular assessments can help maintain optimal performance.

Data analytics and big data play crucial roles in enhancing process control in manufacturing. By harnessing large volumes of data, companies can identify patterns and trends. These insights lead to improved decision-making. For instance, real-time data helps monitor equipment performance. This proactive approach prevents unexpected downtimes.

However, integrating big data is not without challenges. Organizations often struggle with data silos, where information is trapped in isolated systems. This lack of integration can hinder effective analysis. Moreover, the sheer volume of data can be overwhelming. Sometimes, inappropriate data can lead to erroneous conclusions.

Investing in advanced analytics tools is essential. But simply having the tools isn't enough. Employees must also be trained to interpret data correctly. Misinterpretation can result in flawed processes. Continuous feedback loops and iterative improvements are key. Emphasizing a data-driven culture is vital for success in process control.

Process control manufacturing is essential in modern industrial environments, ensuring efficiency and precision in production processes. This article outlines ten crucial techniques in process control, emphasizing the significance of automation in enhancing operational efficiency. Key techniques discussed include PID control and feedforward control, both vital for maintaining optimal performance and quality in manufacturing.

Furthermore, the integration of data analytics and big data plays a pivotal role in refining process control strategies, providing actionable insights that drive continuous improvement. Emerging trends such as IoT integration and smart manufacturing techniques are transforming the landscape, enabling real-time monitoring and adaptive responses to manufacturing challenges. Understanding these techniques is crucial for professionals aiming to excel in process control manufacturing and stay ahead in a rapidly evolving industry.