In the rapidly evolving field of automation and controls, experts like Dr. Jane Smith emphasize the importance of adaptability. "Mastering automation and controls requires both technical skill and a willingness to learn," she states. This sentiment resonates in today's competitive landscape, where staying updated with industry trends is crucial.

As businesses integrate more automated technologies, understanding the underlying systems becomes essential. Effective control solutions can streamline processes and enhance efficiency. Yet, many professionals struggle to keep pace with innovations. Amid rapid advancements, a strong foundation in fundamentals is often overlooked.

Balancing new technologies with established practices is not easy. Challenges arise in adapting to different systems and processes. Some practitioners find themselves overwhelmed by complexity. Reflecting on these experiences is key to growth. By addressing these hurdles, individuals can better equip themselves in the world of automation and controls.

Automation and control systems are transforming industries. These systems help manage and regulate processes effectively. Understanding their basics is crucial for anyone interested in technology and engineering. They consist of hardware and software that enable machines to operate with minimal human intervention.

At the heart of automation are sensors and actuators. Sensors collect data from the environment. Actuators act on that data to perform tasks. For instance, a temperature sensor can indicate when heating systems need adjustment. Such details highlight the intricacy of automation.

However, mastering these systems isn't always straightforward. New users may struggle with programming or hardware integration. Small errors can disrupt processes, leading to inefficiencies. It's essential to approach learning with patience and a willingness to troubleshoot. Embracing mistakes is part of the journey, as it fosters a deeper understanding of how these systems function.

In the realm of automation systems, understanding key components is crucial. Controllers serve as the brain of the operation. They process inputs from various sensors, making real-time decisions. Sensors are essential, providing data about the environment. This data helps in controlling processes more accurately.

Actuators follow the controller's commands, transforming electrical signals into physical actions. They might adjust valves, motors, or pumps quickly and efficiently. Networking components connect various parts of the system, allowing seamless communication. However, the complexity can lead to challenges. Miscommunication between devices may result in unexpected behaviors.

Software plays a critical role in automation as well. It enables monitoring and control of the entire system. Users must grasp how to configure software properly. Small errors in programming can lead to significant issues. Understanding the integration of these components enhances system performance. Yet, many overlook the importance of regular maintenance and updates. A neglected system can quickly become outdated and less efficient.

This chart illustrates the importance of key components in automation systems and their functions. The data represents the percentage of professionals who prioritize each component in their automation projects.

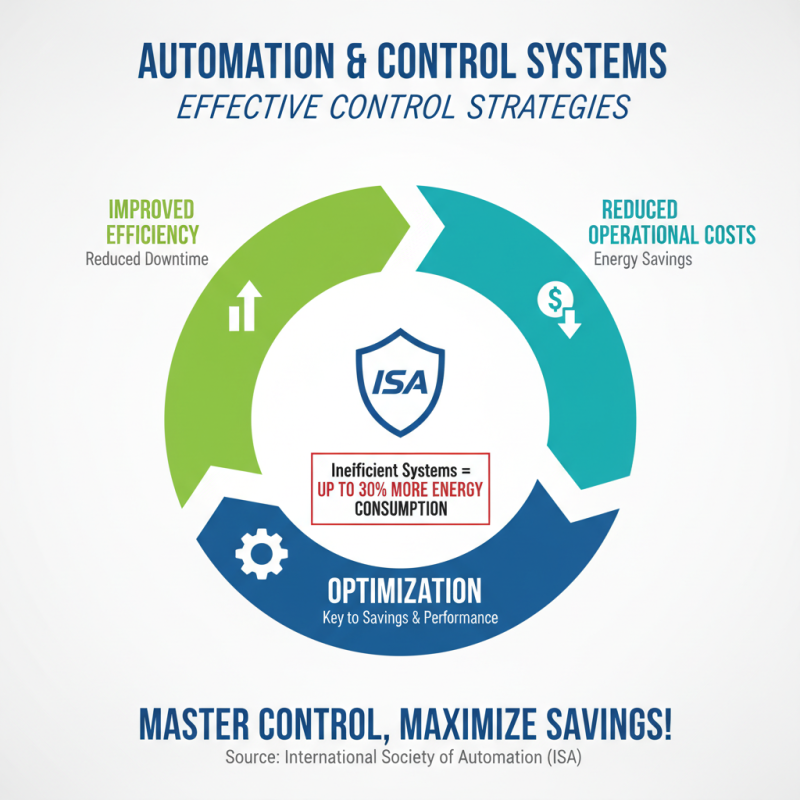

Designing effective control strategies is crucial in automation and control systems. Mastering these strategies can lead to improved efficiency and reduced operational costs. According to the International Society of Automation, inefficient control systems can increase energy consumption by up to 30%. This highlights the importance of optimizing strategies to achieve significant savings.

One of the best practices is to utilize data from real-time monitoring systems. Analyzing this data helps in identifying trends and potential issues. Many firms report that predictive maintenance can reduce downtime by as much as 25%. However, not all control strategies are created equal. Some designs neglect integration with existing systems, leading to further complications.

Flexibility is essential. Control strategies must adapt to changing conditions. A rigid approach can result in lost opportunities. A study by the Automation World suggests that companies with adaptive control strategies see a 15% increase in productivity. Unfortunately, many estates fail to recognize the need for flexibility, leading to outdated and ineffective systems. Monitoring and continuous improvement are key. Striving for perfection in control strategies is a journey, requiring constant reflection and adjustment.

Automation solutions play a crucial role in modern industries. Implementing advanced technologies can enhance efficiency and reliability. These solutions can streamline processes and reduce human error. However, integrating new systems can present challenges. Not all technologies fit seamlessly into existing infrastructures. Careful planning is essential.

Utilizing machine learning and data analytics can optimize operations. These tools provide valuable insights into system performance. Real-time monitoring enables quick responses to issues. Yet, companies must ensure their teams are trained. Without proper training, even the best technology can fail. It's important to foster a culture of continuous learning.

Security is another vital aspect of automation. As systems become more interconnected, vulnerabilities increase. It's not enough to just implement new tools; ongoing assessments are critical. Regular updates and patches are necessary to protect against threats. Companies often overlook these maintenance requirements, which can lead to significant risks. Balancing innovation with security is a constant journey.

| Tip Number | Tip Description | Implementation Strategy | Expected Outcome |

|---|---|---|---|

| 1 | Understand System Requirements | Conduct a thorough needs analysis | Align solution with business goals |

| 2 | Choose the Right Tools | Evaluate software and hardware options | Maximize efficiency in operations |

| 3 | Train Your Team | Organize regular training sessions | Increase overall productivity |

| 4 | Embrace Data Analytics | Utilize advanced analytics tools | Make data-driven decisions |

| 5 | Ensure Cybersecurity | Implement security protocols and tools | Protect sensitive data and systems |

| 6 | Optimize Workflow Processes | Analyze and refine operations | Streamline project timelines |

| 7 | Implement Regular Maintenance | Schedule periodic checks and updates | Ensure system reliability |

| 8 | Foster Collaboration | Encourage cross-department communication | Boost teamwork and innovation |

| 9 | Stay Updated with Trends | Attend conferences and workshops | Incorporate new technologies |

| 10 | Feedback and Continuous Improvement | Gather user feedback regularly | Enhance system performance |

Troubleshooting common issues in automation systems can be challenging. Many professionals face unexpected downtime due to equipment failures or software glitches. Research from the Automation Industry Association indicates that up to 30% of operational downtime is caused by automation issues. This statistic highlights the importance of mastering troubleshooting techniques.

One effective way to improve troubleshooting is to adopt a systematic approach. Identify the problem, analyze the data, and test potential solutions. Documentation plays a key role here. Keep detailed records of past issues. This can help you spot patterns and recurring problems quickly.

Another tip is to ensure regular training for your team. A well-trained team is more adept at diagnosing and fixing problems promptly. According to data from the Institute of Electrical and Electronics Engineers, organizations with continuous training programs see a 25% reduction in error rates. Investing in knowledge leads to better outcomes.

Lastly, consider routine maintenance checks. Neglect can lead to bigger issues later on. Automation systems need regular upkeep to function efficiently. Sensor failures, for instance, can go unnoticed without routine checks. Ignoring small issues may result in costly repairs or downtime later.